The fabric that comes off the loom does not look very presentable - uneven, gray-brown raw material, with protruding fibers. Before it is painted or dyed, it has to go through several stages. They are called finishing.

- What is fabric finishing

- Preliminary finishing

- Finishing of cotton material

- Finishing of linen fabric

- Finishing of woolen fabric

- Finishing of worsted fabric

- Finishing of cloth

- Finishing of natural silk fabric

- Finishing of fabrics made of chemical fibers

- Coloristic finishing

- Fabric dyeing

- Fabric printing

- Final finishing

- Special finish

What is fabric finishing

Finishing of fabrics is a series of successive actions, as a result of which the material released directly from the loom is transformed into finished. These actions are chemical, mechanical and physical processes that improve the appearance, give the material the necessary properties, decorate it.

This is the ultimate goal of the multi-stage textile process - to give the material a marketable appearance. Of course, for different compositions, their own, special processing methods are provided. But in general, for all materials, the following types of fabric finishing can be distinguished:

- preliminary;

- coloristic;

- final;

- special.

Important! At each stage, it is necessary to monitor the temperature regime and the proportion of active chemicals in the solutions involved in the operation. The goal of each of them is to improve the properties while maximally preserving the quality of the fiber.

Preliminary finishing

Initial or preliminary finishing consists of preparing the material before painting or giving the material the properties necessary for bleached canvas. But before the finishing itself, it is necessary to check the quality of the material received for work, to make a rejection.

Finishing of cotton material

Fabrics containing cotton fibers are processed in the following ways:

- singeing - treatment of a surface using a gas torch or molten metal in a trough; protruding ends and excess fibers are removed (material that is subsequently subject to napping, such as flannel, is not treated in this way); the surface becomes cleaner and smoother;

- desizing - removing the strengthening compound from the surface of the threads (sizing); gives softness and the ability to better absorb water;

- boiling - soaking in alkali to wash out organic substances; the process softens the fabric, but gives the canvas a gray-brown color;

- bleaching - removal of natural pigment from fibers by treatment with sodium hydrochloride;

- mercerization is a special treatment of fabric with alkali to give it smoothness and silkiness (for example, for satin fabrics);

- napping - passing the fabric through a special napping machine to obtain a nap on the surface (for flannel, baize).

Finishing of linen fabric

Preparation for subsequent dyeing of linen fabrics is carried out on the basis of a scheme corresponding to cotton, but with some deviations. Linen material goes through the following stages:

- scorching;

- desizing;

- boiling - repeated 2-3 times, each subsequent time using a weaker alkali solution;

- souring - treatment with a sulfuric acid solution to enhance the bleaching effect and remove impurities;

- bleaching - is carried out in four stages, alternating with the processes of boiling and souring for complete or partial bleaching; according to the degree of bleaching, linen fabrics are produced as ¼ white, semi-white, ¾ white and completely white.

Finishing of woolen fabric

Woolen materials are divided into two types: worsted and cloth. Worsted material is thin, light, with a clear pattern of interlacing of threads visible on the front side. Cloth is thicker, and may have a pile. The actual differences dictate special approaches to preliminary finishing.

Finishing of worsted fabric

Includes the following stages:

- scorching;

- washing - removal of animal fat and other contaminants;

- carbonization - used for 100% wool materials; involves treatment with a solution of sulfuric acid followed by drying and subsequent heating; foreign impurities are completely destroyed, while the wool fibers remain intact;

- brewing - alternate treatment with boiling and cold water to relieve stress in the fibers and cause shrinkage;

- wet decatizing - treatment with water and steam on decatizing machines for compaction.

Finishing of cloth

Includes the following stages:

- washing;

- carbonization;

- brewing;

- wet decatization;

- rolling - carried out to impart density and form a felt covering on the surface;

- napping;

- Ratinating is the process of laying the pile in a given direction.

Finishing of natural silk fabric

Silk fabrics undergo fewer processing steps, namely:

- boiling - treatment in soapy water at 95°C for 2 hours to remove pigment and fatty substances; during the treatment, the material becomes soft;

- bleaching - using hydrogen peroxide, the material is bleached until it becomes absolutely white.

Finishing of fabrics made of chemical fibers

They are processed in the same way as natural silk fabrics, but the process is completed with a stabilization stage - exposure of the stretched fabric to steam; this method removes internal tension in the fibers and forms the structure of the material for its further use.

Coloristic finishing

This stage includes dyeing the fabric and applying the pattern in several ways.

Fabric dyeing

During the process of pigment action on the material, it changes its original color. It includes the following stages:

- dye absorption;

- penetration deep into the fibers;

- fixing the dye to the fiber.

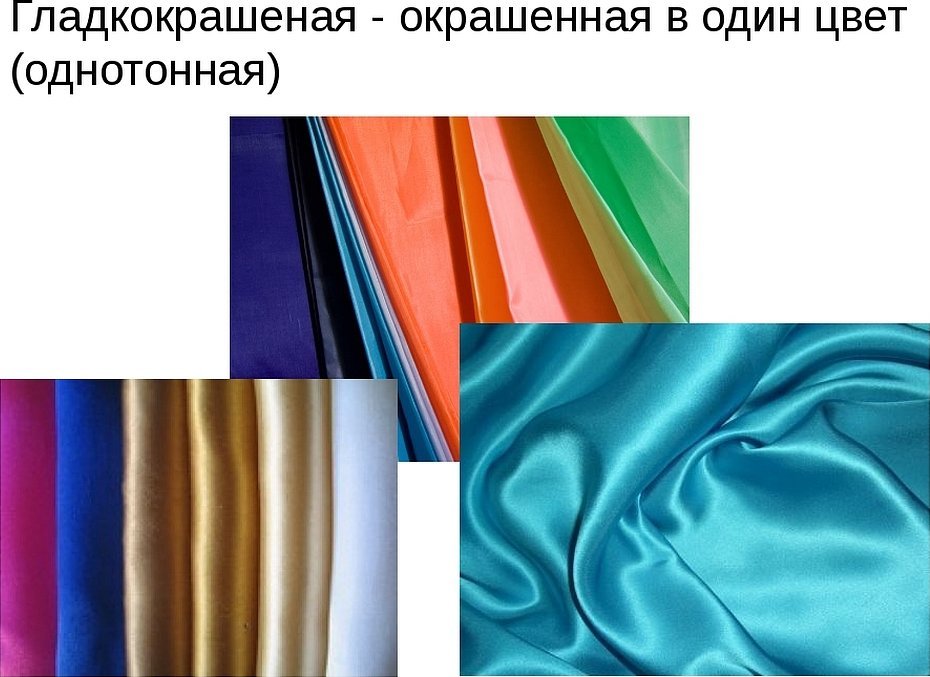

The material is evenly impregnated with dye, resulting in a uniform coloring across the surface and depth of the material. Fabrics dyed in this way are called plain-dyed.

Fabric printing

But not all fabrics should be dyed in one color, for the production of many products it is necessary to apply a pattern, a drawing to the surface, to dye only part of the material. The method of applying various patterns to fabric is called printing. It is performed in various ways:

- direct printing - the design is applied to fabric bleached at the pre-finishing stage or to a plain-dyed surface of light colours;

- etching printing - application of a special etching compound to pre-dyed fabric, the contact points are discolored;

- reserve printing - a protective layer is applied to areas of unpainted material, then the fabric is completely painted; in places where the reserve layer is applied, unpainted areas remain, which form the pattern;

The method of applying the patterns can be manual or machine. Manual, as a rule, is used to create unique, individual items - designer scarves, tablecloths. In mass production, machine printing is used, which has several types:

- thermal printing - a design depicted on a base (substrate) is applied to the material by means of rapid thermal contact;

- silkscreen printing—transferring designs using stencils;

- digital—printing directly onto fabric using an inkjet printer;

- airbrushing - applying a design using a stencil with a spray gun containing a coloring substance;

- Watercolor - applying a design to a damp cloth, which creates a “watercolor” effect.

Final finishing

Final finishing is the final stage in preparing the fabric for cutting and sewing, unless a special type of finishing is required. It improves the appearance and makes further work with the material easier.

The final finishing of cotton and linen materials consists of finishing, widening, and ironing: a finishing agent is applied to the fabric, which consists of an adhesive, softener, and antiseptic; the fabric is leveled on a tenter machine, distortions are eliminated, and the weft threads are straightened; passing through a calender press, the fabric acquires density, evenness, and smoothness.

Woolen fabrics go through the following stages:

- cutting - removes loose fibers or trims the pile;

- finishing;

- pressing—straightening and adding shine to the fabric;

- Decatration—final steam treatment to form stable linear dimensions.

Silk fabrics are treated with a 1% acetic acid solution at the final stage, after which they are sent to dry. As a result, the fabric becomes soft and flexible.

Material made from artificial fibres is dried on needle tenter-shrinking machines with minimal fabric tension.

Special finish

Special finishing is used when the fabric needs to be given special properties, to create a special effect or to eliminate existing defects. Special types of finishing include the following treatments:

- moisture resistant;

- dirt-repellent;

- antistatic;

- anti-crease treatment.

Such processing is most often applied to materials used for sewing work clothes or clothes for special industrial applications - chemical, food.

Also, special finishing allows to improve and shade the aesthetic properties of the canvas. Decorative embossing, metallization, gloss are added, corrugation and varnish are used.

Openwork patterns can be applied to artificial materials, achieving the effect of lush lace. Such material can be used to sew a decorative collar or hem for a dress.

Important information! Metallization involves applying a thin layer of metal to the surface. These may even include precious metals such as gold and silver, which allows for luxury items to be produced. Now this material itself can be used as a finishing fabric.

After passing all the stages and completing all the processes, the output is a variety of material with all the properties it needs. It acquires these qualities thanks to multi-stage finishing.