Technical fabrics are not only a material used for a specific purpose, but also a part of fabrics used in everyday life. Based on the method of use, fabrics are divided into narrow-profile and broad-profile. For example, gauze, which is required not only in medical institutions, but also at home.

What are technical fabrics

Each type of technical fabric has its own function and special purpose. They can be made entirely from natural raw materials, as well as from synthetics, mineral or mixed composition.

The material is classified by density and weaving method. The main advantage is given to linen fabrics. They have increased resistance to mechanical damage, chemical and thermal effects. Such fabric is durable and wear-resistant.

The purpose and properties of the material are determined depending on the characteristics of the fabric composition.

Varieties

Types of technical fabrics and their classification depend on the composition and purpose. They can be fireproof, filtering, heat-insulating. Often the same material is used for several functions. In this regard, the most complete classification can only be obtained based on the composition of the material.

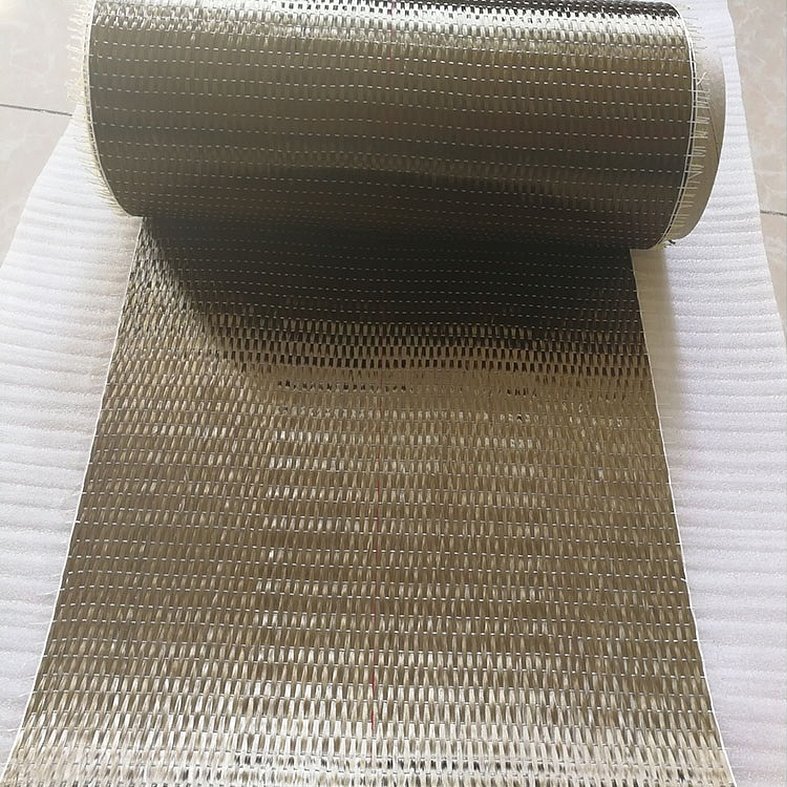

Basalt

Basalt fabrics are made from twisted basalt threads, which are divided by type of weaving into plain, twill and satin. Rocks are used for production.

The material has the following properties:

- non-toxicity;

- environmental friendliness;

- low thermal conductivity;

- very high melting point;

- resistance to alkaline environments, decomposition, rotting, mold and mildew formation.

Due to its properties, the fabric is often used in the construction industry as a heat-insulating material. It is relevant for manufacturers of thermal equipment and aircraft construction.

The fabric can be used as a reinforcing material, but this is only possible in cases where it is necessary to achieve strength, but lightness is required. The heat resistance of basalt makes it possible to use the fabric as special curtains for welding, it is used to make protection for walls located near furnaces and boilers. Basalt material is suitable for the manufacture of wastewater and gas purification filters.

Silica

Siliceous fabrics are made from natural quartz. They can be satin or linen in weaving. The main properties of the material are:

- environmental friendliness;

- thermal and electrical insulation;

- resistance to acids and alkalis, ultraviolet rays, mold and fungi;

- the fabric is able to withstand temperatures above 1000 degrees for a long time. At the same time, all its properties will be fully preserved;

- The working range of silica material is greater than that of basalt.

The fabric is actively used for insulation from high temperatures, and for the production of protective equipment against fires and radiation.

Asbestos

Industrial fabrics made from asbestos threads are called asbestos fabric. This is a harsh, wear-resistant material with thermal insulation properties. The working temperature reaches 500 degrees.

The material is used both in the industrial sphere and in the production of special clothing. It is used to make gasket cuffs and rings, membranes, and gasket fabrics. When sewing special clothing, it is added to protect against high temperatures. The fabric is mainly used in firefighter suits.

Glass

Glass fiber is made from several types of threads. They are resistant to moisture, acids, and alkalis. When producing special thin glass fiber, a coating with a special paraffin-based lubricant is used in production. Glass fiber is used for thermal insulation of pipes.

It is important to pay attention! The disadvantage is the low level of abrasion resistance. Because of this, during operation, it is necessary to additionally protect the material with rubber fiber.

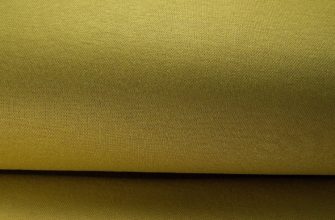

Polyester

Using the technology of plain weave, high-strength fibers are made from polyester threads. This fabric is used to make awnings. The material is resistant to abrasion, durable, tear-resistant, and does not oxidize. It is used as artificial leather, for the production of industrial filters.

Rags

One of the types of fabrics that can be used in various areas due to their soft properties and excellent absorbency is rags. They can be made of cotton or terry cloth. Their main purpose is as a wiping material. It absorbs oils, dirt, paints and varnishes well. Rags are suitable for work in auto repair shops, as they are effectively used to clean mechanical parts.

One of the types of rags is nonwoven. This is a cloth intended for household and technical use. Most often, it is used for wet cleaning and washing floors.

Tarpaulin

Tarpaulin has found its application in various industries. The technical description of the fabric characterizes it as a water-repellent, fire-resistant material. The fabric can vary in density.

Most often, rubberized tarpaulin is used for sewing protective clothing, covering fabric, raincoats, gloves, and shoes. It consists of flax, synthetics, and cotton, which are impregnated with special compounds.

Nylon

Technical nylon fabric is characterized by its durability and smooth surface. Nylon is made from synthetic polyamide fiber. Transparent or milky fabric is also produced. Transparent fabric is considered the most durable. Nylon is several times stronger than silk.

The main properties are:

- resistance to stretching, the fiber does not tear, quickly takes its original shape;

- products made from nylon fabric do not wrinkle;

- the material is very light;

- it is resistant to abrasion and deformation;

- does not deteriorate from bending or twisting;

- easy to care for.

Important! The disadvantages include low lightfastness and the ability to become electrified.

Nylon fabric is used to make curtains, clothing, and decorative items. There is technical cloth, which is used in many industries.

Suede

Technical suede is intended for the production of any type of footwear, leather haberdashery, elements for musical instruments. Suede material is made from deer, goat, and sheep skins. Technical fabric in a roll is produced in accordance with GOST requirements. It has no lint, is excellent for polishing and wiping. Suede does not leave marks or scratches on the surface, absorbs moisture well.

Gauze

Gauze is known to many as a material used for medical purposes. The fabric is woven from degreased cotton yarn.

Technical gauze has the following properties:

- transparency, lightness;

- environmental friendliness;

- possibility of sterilization;

- absence of impurities during production;

- hypoallergenic.

Strict requirements are applied to the production of gauze, as it comes into contact with open wounds. The fabrics are subject to careful control. This is necessary to exclude the presence of dangerous chemical impurities in the fibers.

Standards and GOSTs

All technical canvases are produced based on the documentation standards established by GOSTs. Canvases are assigned special articles that indicate the presence of certain properties. This is an important aspect in production, since it is due to the articles that the area of application of the material is determined.

Most often, technical fabrics have no analogues, each type has its own technical characteristics. Production of fibers with lower characteristics is not allowed.

The production of various types of technical fabrics is a broad industry. The manufactured material is used in various fields, from construction to medicine.