Sound plays a huge role in modern technology. Sounds are constantly mixed, and the problem of isolating the necessary frequencies has existed since the invention of radio. Simultaneously with the improvement of technology, the materials for its manufacture were improved. One of the oldest materials, which appeared almost 100 years ago, is acoustic fabric, called radio fabric in those years.

Its main purpose was to mask the receiver parts and sound devices. At the same time, it had to transmit sound without distortion. Today, acoustic fabrics are produced in several types. The material will examine in detail their varieties, properties and areas of application.

Structure and properties of acoustic materials

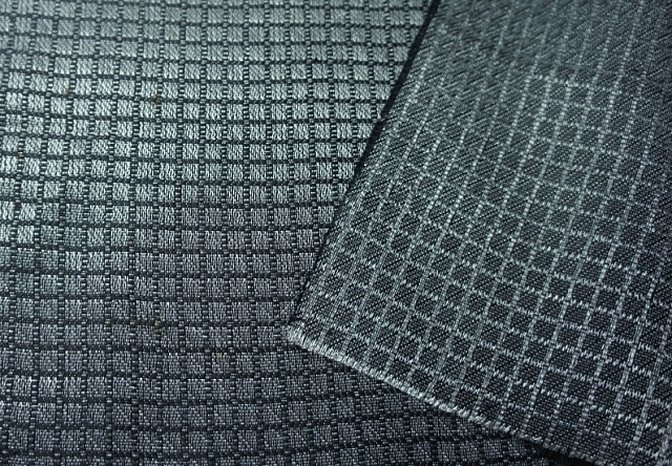

The very first acoustic fabric was made of cotton and, less frequently, silk. The fabric was woven in a special way, which can be seen on old radios and sound equipment. Modern materials for these purposes are made primarily of polyester.

The fabric can be woven in different ways, forming a mesh grid, and have different colors: from white and black to multi-colored, and contain signature patterns that identify the manufacturer of the material.

Important! The density, texture and elasticity of the material may vary depending on its purpose.

It is used to decorate audio and acoustic music systems, to create the effect of a favorable acoustic environment. Fabrics are woven from threads of different thickness and shade. As a result, a huge number of textures are obtained. Some types are treated with a special impregnation based on fire retardants to give them fireproof properties.

The main characteristics of this type of fabric are:

- High strength index;

- Wear resistance;

- No reactions when interacting with most chemical compounds;

- Low hygroscopicity;

- High acoustic effect, transmission and reflection of sound signals;

- Certain types of fabric are resistant to high temperatures and fire.

Varieties

Today, acoustic fabric is actively used not only for decoration, but also for use inside devices. At least two types of material can be found on the market:

- Sound-transparent, that is, sound-permeable;

- Sound absorbing.

The first type of fabric can be attributed not only to decorative, but also to sound. Its main purpose was to shield the internal parts of the equipment and protect them from mechanical damage, especially speakers. Such fabric is acoustically transparent.

Important! Sound-transparent fabric can be very thin and look like chiffon, or it can be thicker, like loose matting.

The main requirement for this type of fabric is the free transmission of sound without any distortion. Since sound devices play an important role in interior design, such fabric should be attractive and have many colors to suit a specific interior.

The main property of sound-absorbing fabric is the absorption of sound signals and waves, especially those that are reflected from walls and interfere with the main signal. Such material is denser and more porous. It is ideal for placing it on walls in rooms where sound quality is important: recording studios, concert halls, home theaters. The use of such textiles in cars has become a trend in recent years.

Important! This type of sound-absorbing material, placed on the ceiling and walls, not only creates comfortable conditions and protects from noisy neighbors, but is also a good design element.

According to their varieties, this type of fabric can be divided by the material from which they are made, namely: velvet, blackout or multi-layer curtains.

Velvet

The most common material. Its advantages are that it is pleasant to look at and touch, and also perfectly absorbs sound signals. For acoustic purposes, thick and dense velvet with a long pile should be chosen. It is most often used for finishing bedrooms, conference halls, museums.

Blackout

Blackout not only protects from 90% of the sun rays penetrating from the outside, but also insulates sound. It can be draped or used as curtains and drapes. It is perfect for insulating bedrooms, photo labs, and movie theaters.

Multilayer curtains

Soundproofing curtains are made from several types of materials: wool or polyester. Today, they do not necessarily have to be multi-layered, since types are being invented that transmit light well, but are acoustic and can replace curtains made in several layers. Such curtains are used not only in apartments, but also in public places, restaurants, cinemas.

Applications of acoustic fabric

High ceilings, flat floors and reflective building materials cause interference of sound waves and echo. It is impossible to listen to music in such a room without echo and extraneous noise. It is for such rooms that acoustic fabric is used, which is used to cover the walls, ceiling and wall joints. This is an excellent solution not only for living rooms, but also for recording studios.

Important! Covering walls and their joints with such materials will not only improve the acoustics of the room and correct the sound, but will also fit into the interior if the manufacturer and properties are chosen wisely.

In addition to the decorative and soundproofing function, acoustic fabrics are used to protect speakers and other elements of audio systems and speakers from mechanical impacts. This is explained by its strength properties.

Acoustic fabric for speakers

Due to the protective properties of the fabric, it is used to cover speaker grilles and other elements of acoustic systems, as well as for decorative design of subwoofers. Acoustic fabric made of polyester stretches in different directions and therefore easily covers objects of various shapes to give them sound insulation or sound transmission capacity. It is easy to dye, due to which brand names and logos are often depicted on it.

Acoustic fabric or speaker fabric is a fairly old type of material used in the creation of audio and radio equipment, in its design, as well as in the design of rooms where sound insulation and the absence of reflections of sound waves are important.