The presence of extraneous loud noises can not only spoil the mood, create discomfort, but also harm health. Soundproofing equipment issues are relevant, first of all, where there are sources of strong noise or there is strong sound permeability. One of the effective ways to solve such problems is to use acoustic felt.

Purpose and areas of application

Acoustic felt is a high-density material that is sold rolled into rolls. It can be used for soundproofing in the following situations:

- wall and ceiling cladding, including those made from thin timber;

- when installing suspended ceilings;

- in pitched roofs;

- for installation of suspended ceilings;

- for floors, self-adhesive felt can be laid on joists;

- insulation is required due to the use of equipment that produces a lot of noise during operation;

- for soundproofing the interior and trunk of a vehicle;

- Soundproofing may be necessary when using large diameter pipes;

- to protect against noise associated with ventilation and air conditioning.

Sometimes protection from excessive noise may be required if it is related to certain types of activities. This is important, for example, in the following cases:

- In recording studios.

- In rooms where flow-through exhaust systems are located.

- To isolate the sound that occurs in a movie theater when watching films.

- When operating pumping units.

Soundproofing is used not only to improve conditions in rooms, but also to create a more comfortable environment in the car interior.

In this case, protection from external noise and engine echoes is needed. It is necessary to take into account that excess noise not only creates discomfort, but also harms health.

Felt can be used to improve the acoustics in a room.

Please note! If necessary, the material can be dismantled and reused.

Types of felt for sound insulation

This material has several varieties:

- The most common is coarse wool felt. It is used mainly in construction. Sometimes this type is produced as self-adhesive felt, which allows it to be fixed to a wall or other necessary place.

- Sometimes multi-layer acoustic felt is produced, which includes a built-in membrane that enhances its soundproofing properties.

- Needle-punched felt is a non-woven material. Its fibers are bonded by piercing with special needles. This variety has found wide application in sewing clothes and shoes, for furniture production and soundproofing of car interiors and trunks.

- There are special types of felt. They are made using complex technologies for use in certain situations (for example, as a base for a floating floor, for use when installing a stretch ceiling or when installing utility elements).

Typically, the thickness of coarse wool felt is 10-12 millimeters. One of the most well-known brands is acoustic felt StP.

For use as a soundproofing layer in a car interior, it is convenient to use automotive felt, which is hermetically sealed in cellophane. This is due to the ability of felt to actively absorb moisture, including from the air. Such insulation is placed under the car mat and, due to moisture insulation, serves for a long time without losing its quality.

Technical specifications

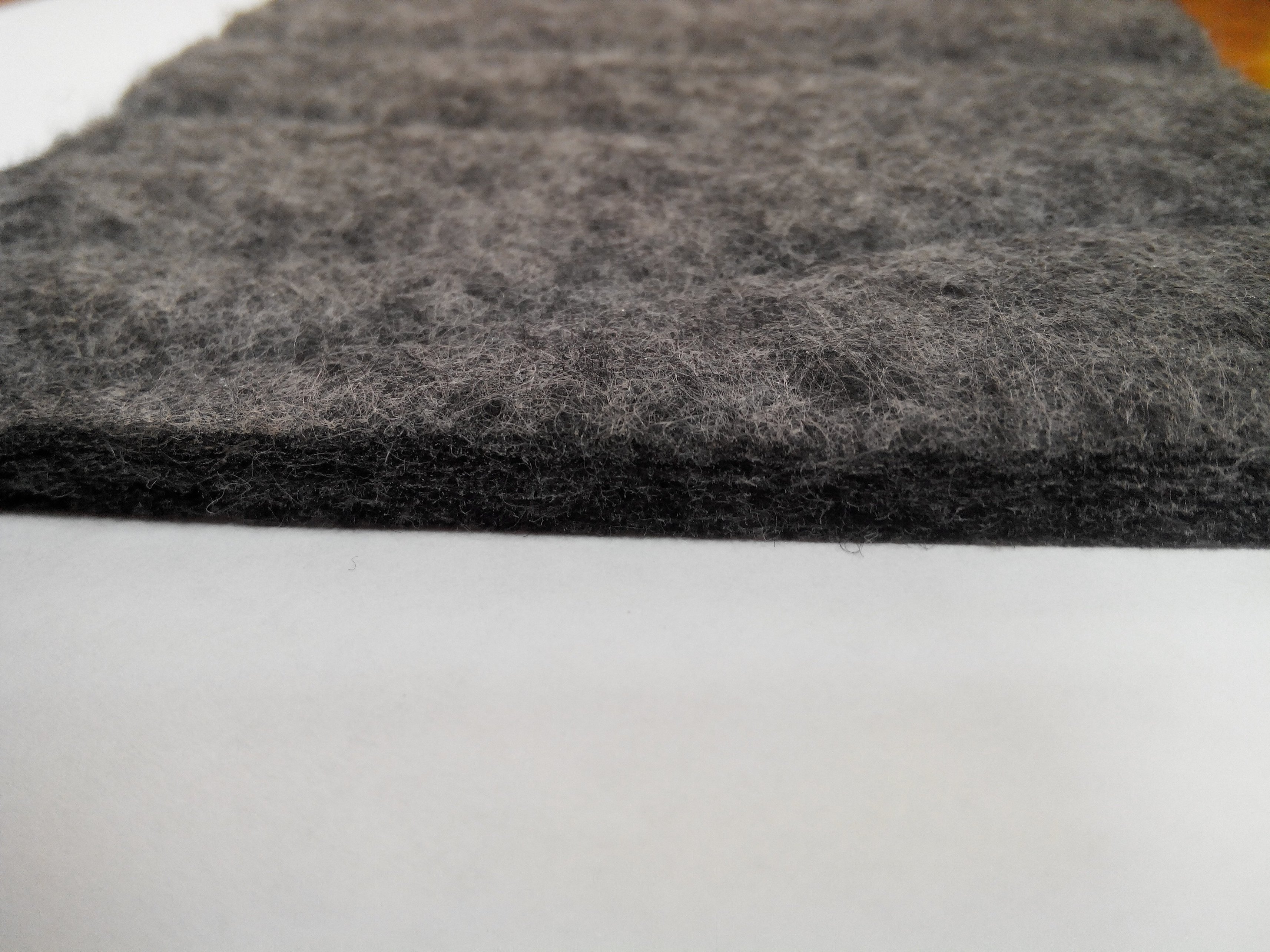

This material is made from the wool of some breeds of sheep, as well as from polyester fiber, which has similar qualities. No adhesives are added to its composition. The felt material has good mechanical strength, elasticity and durability. Throughout the entire period of use, the material completely retains its useful properties.

Soundproofing felt has a fibrous structure and is able to actively absorb moisture and retain it inside. Once the sheet gets wet, its soundproofing properties deteriorate significantly.

The density of coarse wool felt is 1500 grams per square meter. It is most often produced in sheets measuring 2.5 x 1.2 meters.

Additional information! This material is not fire hazardous and is not prone to rotting. Felt is able not only to reflect sound, but also to absorb it. One of its important features is ecological purity and hypoallergenicity. If you use this material, even people suffering from allergies will not experience any inconvenience from it. This material does not leave any debris, individual fibers and does not emit dust when used.

The use of felt is also beneficial because it is cheaper compared to other noise-insulating coverings.

Acoustic felt has high crushability. This allows it to be laid in hard-to-reach places and where there are sharp corners or a surface of complex shape, and easily placed in the car interior.

In addition to protecting against noise, the material has good thermal insulation properties.

The light weight of the felt allows it to be easily transported and installed.

DIY installation

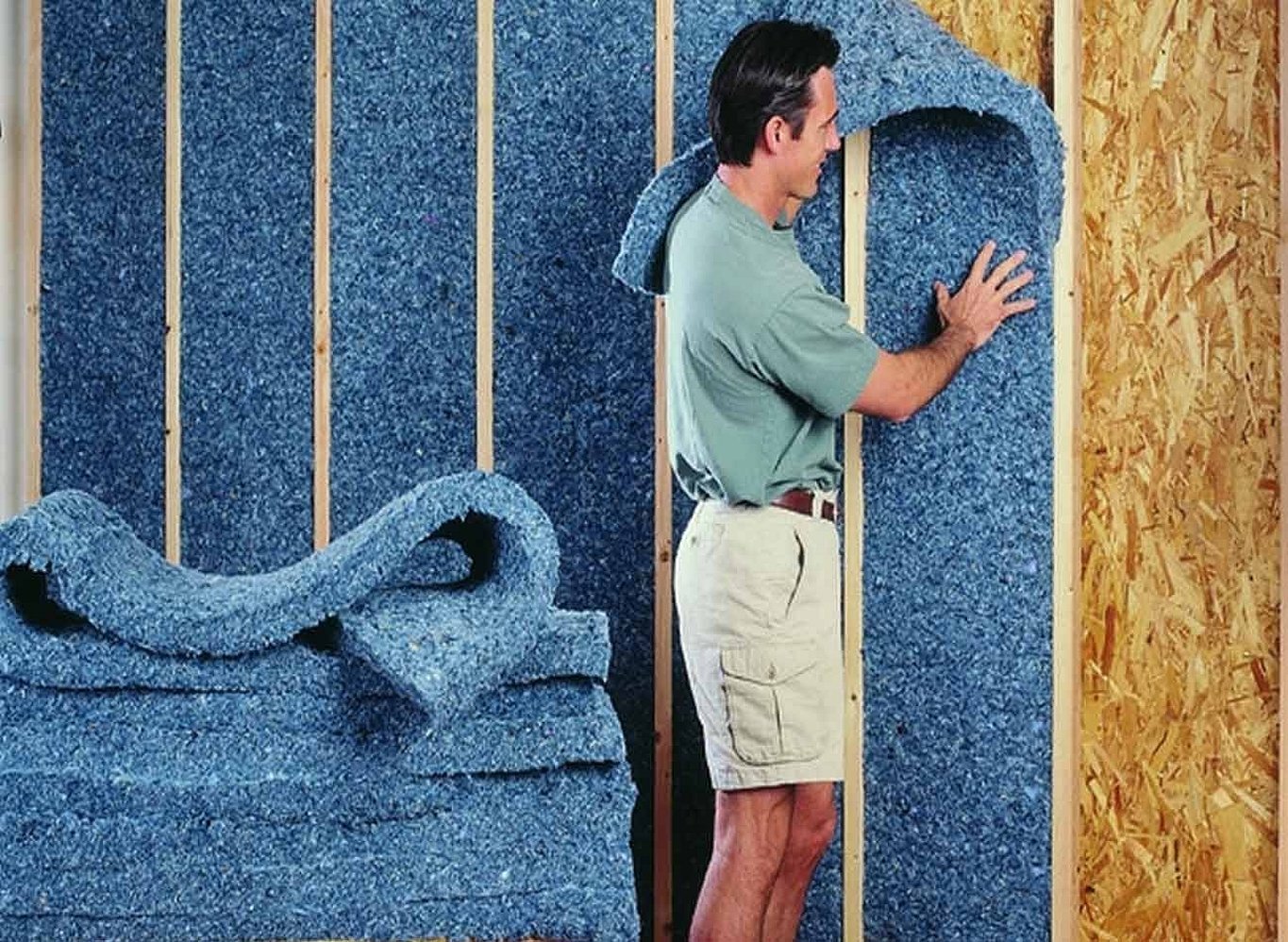

If you need to install soundproofing in an apartment, you first need to make a plan for the work. It is not always necessary to cover all the walls with a protective layer; sometimes it is enough to treat only one or two of them. In other situations, it may be necessary to think about soundproofing the floor or ceiling.

When carrying out work, it is necessary to take into account how effective the insulation is required. Sometimes it may be enough to use a thin layer of acoustic felt, while in other cases a material of significantly greater thickness will be required.

It is important to remember that there is no point in using a single layer of felt when working in an apartment. As a rule, several layers of materials are needed, each of which performs certain functions, including the final finish.

Therefore, two installation options can be considered:

- Using a thin layer. This is necessary if very powerful sound insulation is not needed or if the work is being done in a small apartment.

- Use of powerful protection. This is required where residents are constantly affected by loud sounds coming from outside.

First, we will consider the procedure for carrying out work in the case when the owner needs a relatively thin protective layer for the apartment.

The procedure for installing the material on the wall will be described. Soundproofing installation is performed as follows:

- It is necessary to clean the wall from dirt, remnants of old wallpaper and other debris.

- If there are any uneven areas, cracks or potholes, they must be carefully filled with putty.

- It is necessary to pay attention to the places where the pipes come out. There may be gaps between them and the wall, which should be sealed with acoustic sealant.

- Additionally, it is necessary to treat the wall with a deep penetration primer. It will seal cracks that were not noticed before and will make the surface have higher adhesion to the coating. In addition, such treatment will serve as an obstacle to the formation of pathogenic flora.

- Then they use a special sound-absorbing membrane, gluing it to the wall surface.

- After this, hot fiber sheets (GVL) are installed, attaching them to the wall with special dowels and screws.

- Then a layer of self-adhesive acoustic felt is laid. In most cases, it is not necessary for it to exceed 1 centimeter.

- After this, another layer of hot fiber sheets is placed.

The total thickness of the layers with this method of laying does not exceed 3.7 centimeters. The felt and gypsum fiber sheets must be laid so that there are no gaps between them. On the outer layer of hot fiber sheets, it is necessary to seal the gaps with putty.

You can glue wallpaper or do other final finishing of the wall on such a protective layer.

If a thick layer of sound insulation is required, installation will be more labor-intensive. In this case, the recommended procedure will be as follows:

- It is necessary to prepare the wall surface. To do this, it is cleaned, potholes are filled and treated with putty.

- Then the membrane is glued.

- A frame is installed on the wall. It can be made from a metal corner or wooden beams. In the latter case, the strength will be significantly lower. Acoustic felt is placed in it. Mineral wool can be used instead, and a layer of felt can be installed on top of the frame.

- Plasterboard or gypsum fiber board can be used as the top layer. After installation, the cracks must be hermetically sealed.

Such a soundproofing layer can reach a thickness of seven or more centimeters. It can make the wall much thicker, but at the same time provides high-quality soundproofing.

When installing a protective layer in the interior of a vehicle, self-adhesive felt for cars can be used.

In order to create comfort, many things are necessary, but good sound insulation is one of the first places. Using felt for noise insulation allows you not only to solve such problems, but also to do it at moderate costs.