Polypropylene fabric is a multifunctional high-quality coating that is actively used in various areas of life. This synthetic product allows for safe transportation and storage of any products and goods.

Features of the production of synthetic polypropylene material

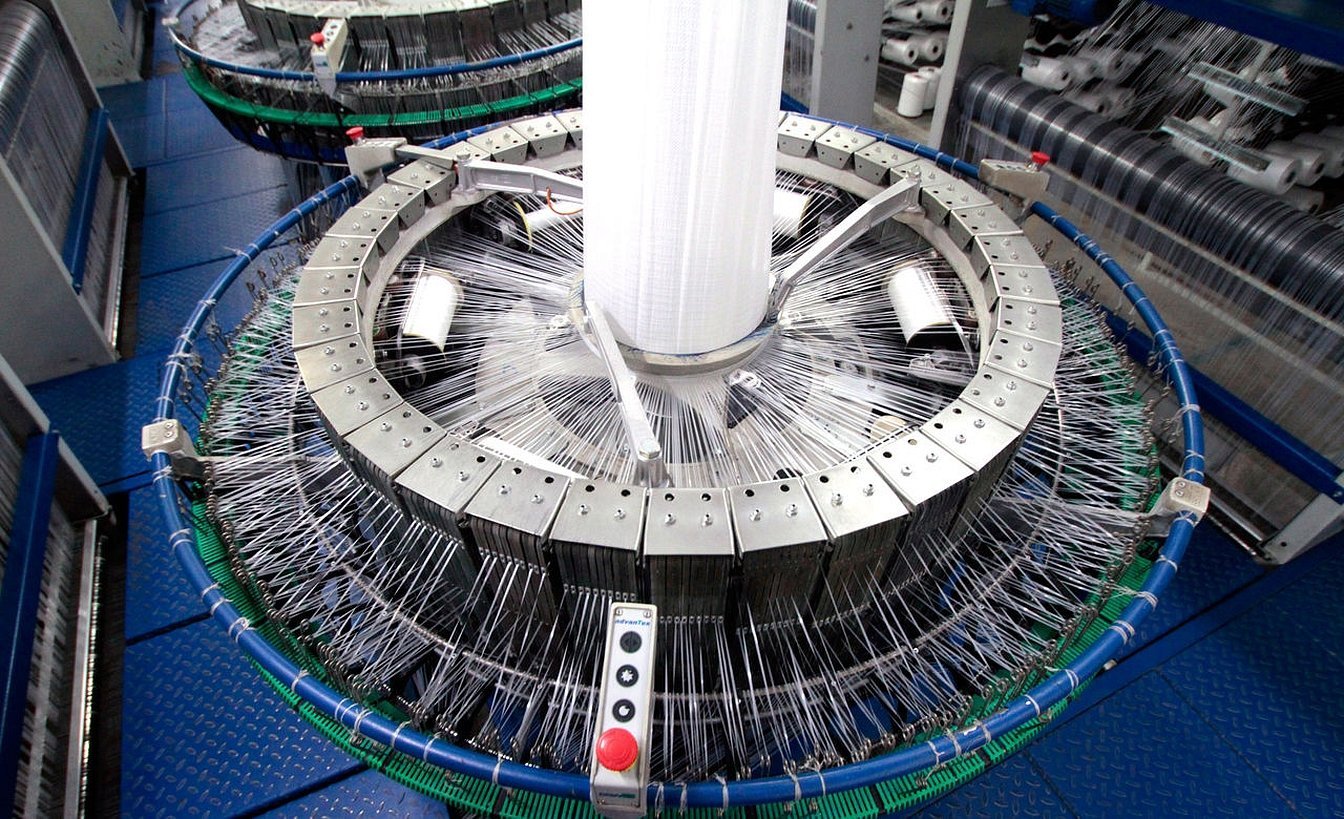

How is polypropylene fabric made and what is it? This material is formed by weaving thin fibers on special plant equipment. A distinctive feature of the thread is its low density: about 250,000 meters of fabric are made from 1 kg of raw material.

Polypropylene fabric can be made waterproof by laminating it with polyethylene. The procedure is carried out due to the difference in melting temperatures of these materials. Lamination allows not only to increase water resistance, but also to give the material the following characteristics:

- Protection from ultraviolet radiation.

- Dustproof.

- High strength.

- Long service life.

Characteristics, properties and features of polypropylene fabric

The main feature of the fiber is the low cost of its production. Also, the properties of such material include:

- High strength. Products based on such fabric are capable of withstanding heavy loads and pressure. This significantly increases the service life of the fabric.

- Safety. The raw materials used in the production of the canvas are environmentally friendly. This allows the material to be used for storing various food products without fear of the release of harmful substances.

- Protection from temperature changes, so you don’t have to worry about the safety of your goods during transportation.

- Chemical resistance. The material is perfectly protected from the effects of any chemicals.

Types of polypropylene fabric

An undoubted advantage of polypropylene is the possibility of its secondary processing. This allows manufacturers to create a large number of types of fabric that are used in various fields. The main ones include:

- Transparent polypropylene fabric. It has excellent mechanical protection indicators and a long service life. Such material does not need to be painted with special additives.

- Colored fabric is produced by adding special additives to the raw material. The final product can have any shade. The material is resistant to ultraviolet rays.

- Reinforced polypropylene. To increase the strength of polypropylene fabric, manufacturers weave in reinforcing threads or wire at the production stage. This significantly increases the rigidity of the fabric and provides additional protection from external mechanical impacts.

- Spunlace. A type of woven polypropylene. In its production, the fibers are bonded under water pressure, which makes the material smoother.

- Spunbond and thermobond. The fabric is produced using the spinning method. The material is the basis for the production of wet wipes, shoe covers, tablecloths, etc. Thermobond is often used as the top layer in feminine hygiene pads.

Applications of polypropylene fabric

A huge number of companies are engaged in the production of polypropylene fabric, as it is in great demand. This coating is used in various fields. The main list includes:

- Construction. Although woven polypropylene fabric has good strength, it also allows water to pass through perfectly. It is used when laying the foundation to evenly distribute loads and prevent soil movement. Polypropylene bags are also an excellent solution for packaging construction waste.

- Agriculture. The material is used to make geotextiles. It is laid between different layers of soil for separation. This helps prevent weeds and save a lot on weeding. Polypropylene is often used in the construction of greenhouses and hotbeds. Laminated material warms the ground before planting various plants.

- Landscape design. Polypropylene is used for the construction of various decorative elements on a summer cottage.

- Mechanical engineering. Truck awnings are made from this material, and it is used as a covering on railways. Recently, wagon liners have become popular, which help to avoid product losses during transportation. They also protect the body from dirt and precipitation.

- Furniture. Durable polypropylene is used in the manufacture of sofa beds or as upholstery for armchairs and loungers.

- Medicine. Polypropylene fiber is used to make hygiene products. This material is also used to create syringes, droppers, and inhalers.

- Electrical engineering. The material is used for insulation of various cables.

- Automobile manufacturing. In this industry, polypropylene fabric is used as a filter for cleaning oils and other liquids.

- Household goods. The availability of polypropylene allows it to be used to produce everyday items: blankets, pillows, bags, outerwear and other items.

Please note! Polypropylene protects the human body well from high humidity, so it is often used in the production of thermal underwear. But it is worth considering that wearing such clothes for a long time is not recommended, as it dries out the skin and retains an unpleasant odor.

Advantages of non-woven polypropylene material

Non-woven polypropylene has a number of undeniable advantages. These include:

- Possibility of application in many areas of industry.

- High strength and resistance to mechanical impact.

- High temperature does not change the structure of the material.

- Protection from chemical exposure.

- Pleasant tactile sensations.

- Completely environmentally safe material.

- In terms of weight, polypropylene is significantly lighter than other plastics.

Polypropylene fabric is an indispensable material. It is used in many areas of industry and is characterized by low cost and excellent strength indicators. This material is simply indispensable in the transportation of various products, in construction, agriculture and other areas. Various bags and garbage bags, personal hygiene items and much more are made from it.