Once upon a time, people did not know about PU fabric. They could only read what it was on the packaging or badge. The materials were of poor quality and harmful to health. Modern technologies give us the opportunity to use leather substitutes and many other materials made of polyurethane. They are not inferior in quality to natural ones.

- What is polyurethane

- Features of the production of the presented material

- Properties and technical characteristics of the material

- Application areas

- How does a polyurethane jacket wear in general?

- Compare with similar jacket materials

- Polyurethane or Faux Leather: Which is Better?

- Polyester or polyurethane: which is better

- Hollowfiber or polyurethane foam: which is better

- Pros and cons of the material

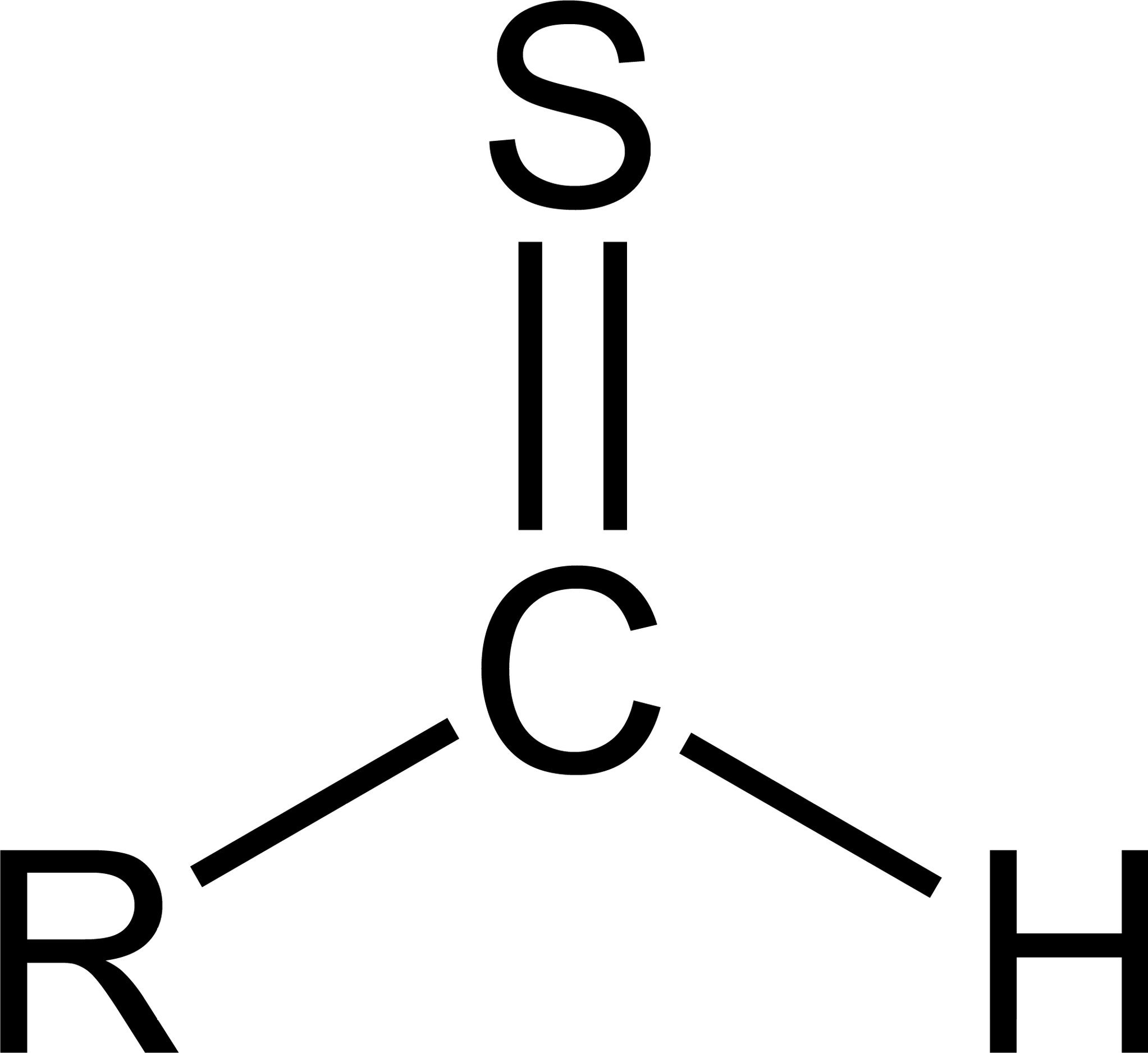

What is polyurethane

Polyurethane (polyurethane, polyuretan) is a substance produced by artificially synthesizing a polymer. It has subtypes. It has received wide application due to its qualities. The material is very similar to rubber. It is used to produce elastic products, seals, bushings and washers.

Features of the production of the presented material

There are 2 methods of producing polyurethane:

- Pouring method - used for manufacturing panels, blocks, decorative elements. Performs the properties of insulation.

- Spray method - is carried out with special equipment using foam or pouring. This method is included in the process of the first method.

The generator has access to tanks for automatic mixing of components. The resulting mass is directed into a chamber, which is connected to a sprayer and to another tank for pouring the mixture into molds. During polyurethane molding, dosing is strictly automated.

The production process is controlled by a specialist. All information is displayed on a digital screen. Spraying and pouring processes occur at high speed. This ensures high performance. The equipment is easy to maintain. The automation process and high technology allow obtaining high-quality polyurethane.

Properties and technical characteristics of the material

Main properties:

- Durability, wear, strength - the difference of polyurethane polymers. It tolerates well being in solvents and oils of organic production. It does not decompose under radiation. This indicates that it is the best material in operational characteristics.

- The strength of polyurethane is better than that of rubber, rubber, metal. Its application is aimed at technologies with metal stress. In comparison with other materials, the resistance of abrasive polyurethane is much higher.

- When heated, deformed and broken, it does not lose its properties. On the contrary, it acquires new ones.

- At high hardness it remains elastic. Its deformation limit is considered to be 350%. It remains intact even at 50 MPa. It withstands dynamic stresses at a temperature of 120 °C. The elastomer remains unchanged at -70 °C.

- Polyurethane has strong dielectric properties. They are not subject to dissolution in solvents and oils. They are not destroyed by ozone. They are resistant to bacteria and mold.

- Polyurethane items can take various forms. This cannot be said about rubber ones. Polyurethane manufacturing technology is cheaper than rubber and caoutchouc.

Please note! The only downside is the problem of recycling polyurethane waste.

Application areas

There are several types of polyurethane.

- Foamed. Used in the construction and furniture industries. Lightweight, waterproof material. Included in the composition of thermal insulation materials.

- Liquid. Roofing is made from it.

- Sheet and cast - in the automobile, construction industry and medicine. Sealing rings, silent blocks - all this is made of polyurethane.

How does a polyurethane jacket wear in general?

Polyurethane fabric has been used in jacket production. They are very strong, durable and hygroscopic. In the rain, such a jacket will be simply irreplaceable. Polyurethane fabric has microscopic pores and is perfectly breathable. Such a jacket has a wrinkle-free structure. Suitable for everyday wear.

The prices are affordable. The colors and styles are in a wide range. In addition to the advantages, there are also disadvantages:

- Cannot withstand freezing temperatures.

- Washable on delicate cycle only.

Compare with similar jacket materials

For a long time, leatherette and leather substitutes were made from synthetic materials. They had an unpleasant smell and an unsightly appearance. They were subject to rapid wear.

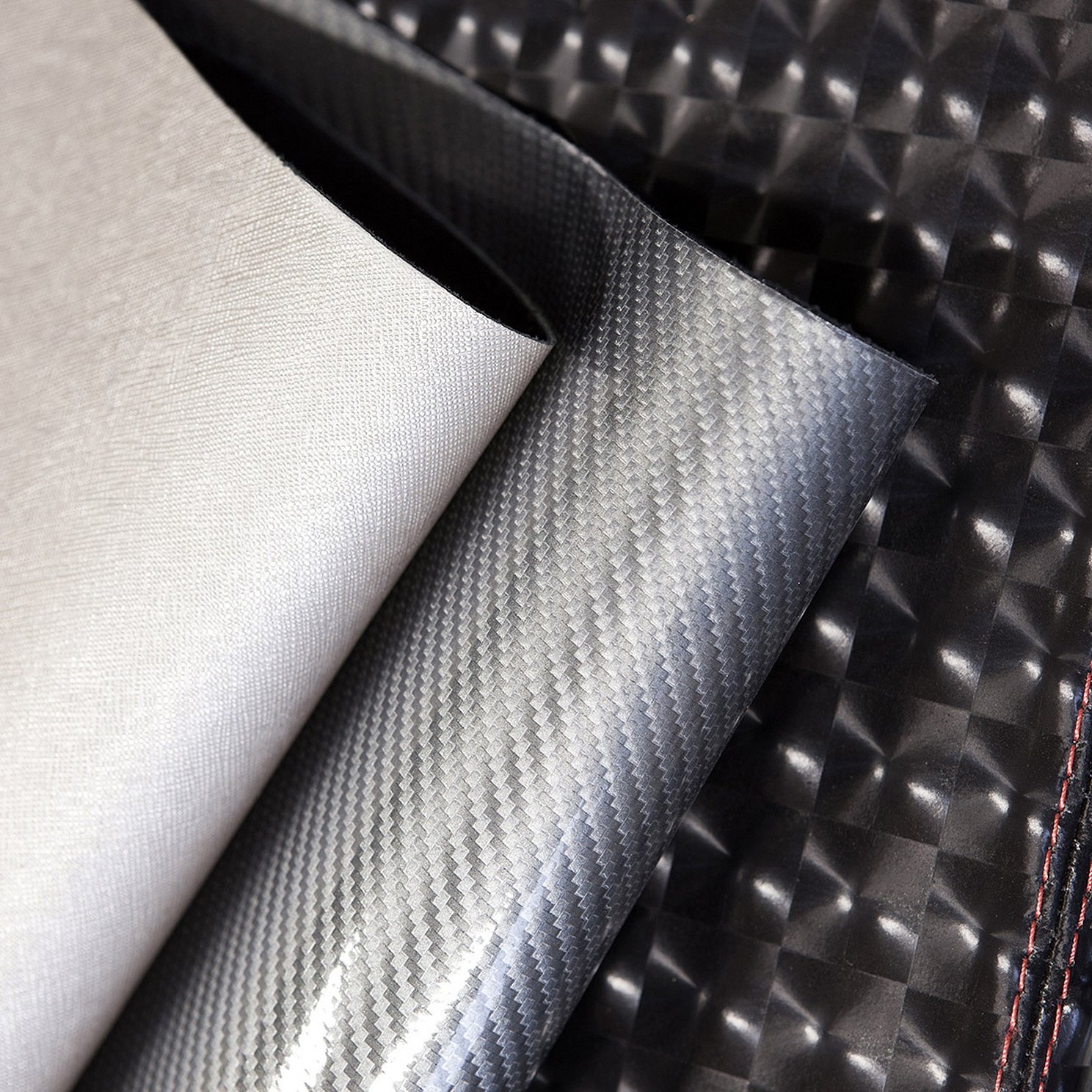

Polyurethane or Faux Leather: Which is Better?

As a result, people began to distrust things of this type. Modern manufacturing technologies can greatly change people's attitudes towards eco-leather for the better.

Additional information! The first samples of eco-leather were made in 1963 in the USA.

Eco-leather contains polyurethane. This is a fine-pored polyurethane layer attached to a cotton or polyester base. When they are combined, a pattern is obtained that is very similar in texture to leather. Visually, it is indistinguishable from natural material. It may differ only on the back side.

Polyurethane fabric or what it is can be found out by touching it. Such material has good elasticity. Pleasant to the touch. The thickness of the top layer of polyurethane affects the quality of the material. The thicker the layer, the stronger the product will be. Rigidity also depends on it.

Eco-leather has many positive qualities:

- Good air permeability. Air circulation passes through micropores. This is especially important in jackets and shoes.

- Waterproof.

- Thermal conductivity. Compared to natural leather, it maintains the required temperature at any time of the year.

- Frost resistance. Capable of withstanding up to -35C. Does not fade when exposed to sunlight.

- Products made from this material do not lose their appearance.

- Eco-leather does not have an unpleasant odor.

- Does not cause allergic reactions.

- Does not contain harmful elements of polyvinyl chloride and plasticizers.

- No animals are harmed in the production process.

- Affordable price compared to genuine leather.

Eco-leather is used to make:

- Clothes - jackets, skirts.

- Accessories-gloves.

- Shoes.

- Upholstery for furniture.

The PU fabric is easy to handle. It cuts well and does not slip.

Important! Chlorine-containing substances cannot be used to clean eco-leather.

Cons:

- Water, when it hits the surface, leaves marks and stains.

- If the material is not made correctly, it can absorb paint from the fabric.

- If damaged, the fabric base comes out.

- Requires water-repellent treatment for long-term service.

Artificial leather - is made from animal skins and undergoes a number of procedures with the addition of chemicals. Types of procedures:

- Soaking.

- Gilding.

- Tanning.

- Painting.

All these processes are carried out with the help of chemicals. They cause great harm to the environment. Products made of genuine leather are considered a sign of prestige and cost a lot of money.

The only positive quality of genuine leather is its durability and strength. Taking care of it requires a lot of time and effort.

By exploring the differences between materials, the buyer can decide for himself what is best for him.

Polyester or polyurethane: which is better

Polyester has some advantages:

- Water resistance.

- No pilling, snagging or other problems on the surface of the material.

- Resistant to dirt.

- Does not deform.

- Durable and long lasting.

Polyester clothing is currently considered the most popular. It has many more advantages than disadvantages.

Please note! When comparing polyester and polyurethane, the difference is not particularly noticeable.

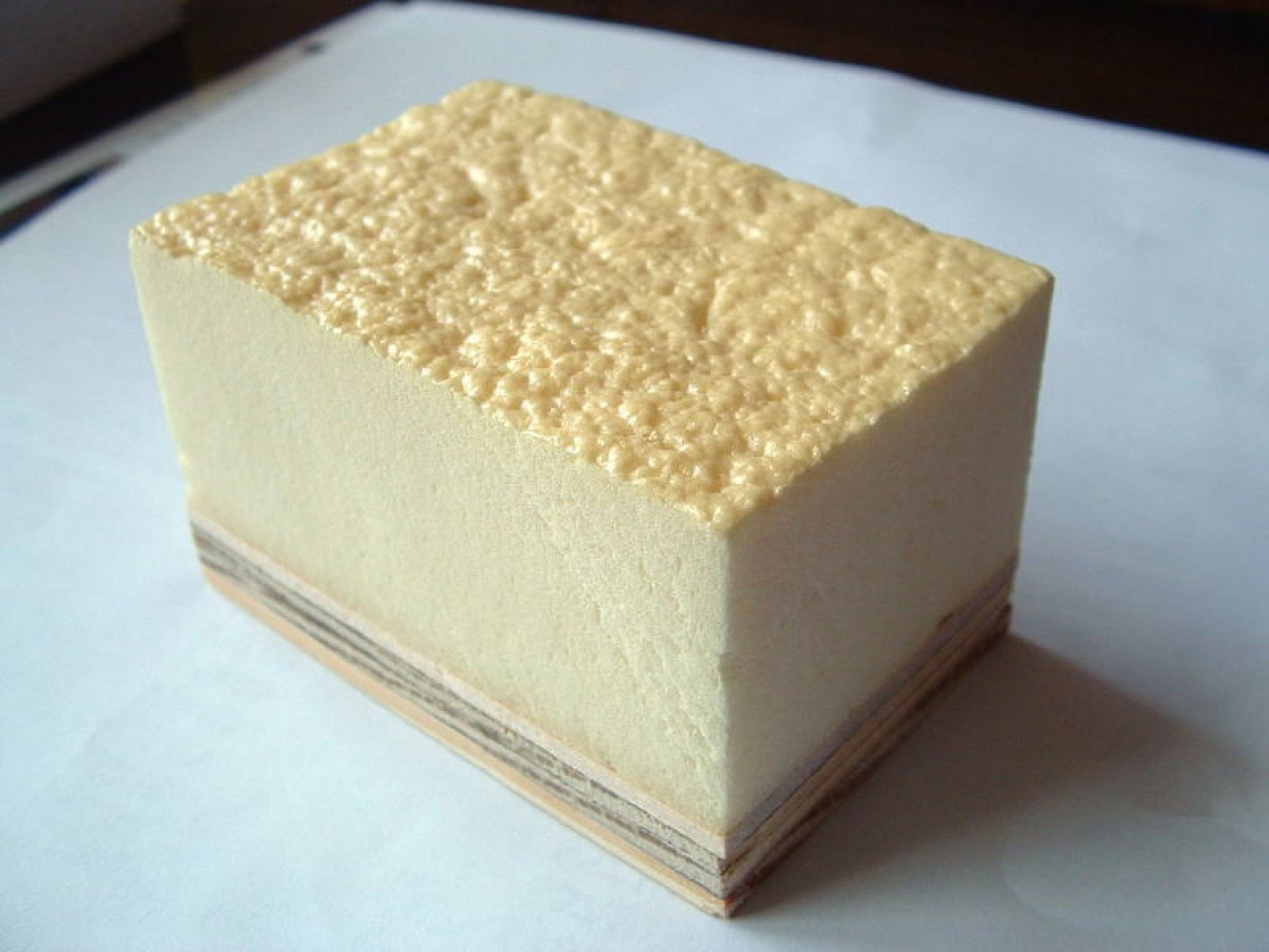

Hollowfiber or polyurethane foam: which is better

Holofiber is a chemical fiber made of polyesters. It is produced only at the Termopol plant in Moscow. The filler, tight to the touch, consists of synthetic fiber. Thermal impact during production is the key to excellent performance properties. It is used to make mattresses and pillows. It is used to fill the mattress pad. It has a low cost. Holofiber mattresses are practical and correctly distribute the body load regardless of weight.

Important! The question is often asked: struttofiber or holofiber, which is better? They are very similar in quality to each other.

Polyurethane foam or PPU is also used to fill mattresses. It was released much earlier than Hollowfiber. It became a revolutionary discovery in this industry.

It has an inexpensive price, different rigidity and is suitable for spring mattresses. In the springless version, harder foam rubber is used. Suitable for people with a lot of weight.

Polyurethane foam filler is considered cheap and practical on the market. Due to this, it is very popular among the population.

Pros and cons of the material

Description of advantages:

- Does not conduct electricity. Used in the energy sector.

- Does not oxidize. Suitable for the production of building materials.

- Doesn't get wet.

- Lasting.

- It weighs little.

- Long lasting.

- Stretches well. Stretch percentage is 600.

Cons:

- Does not deform well.

- Airtight.

- It is poorly recycled as secondary raw material.

The properties of polyurethane depend on the type of urethane group, molecular weight and crystallization level. It can be elastic and at the same time hard. There are constant disputes about what is closer to polyurethane - rubber or plastic. In fact, neither. From a chemical point of view, they have different compositions. The main advantage is that it can withstand aggressive environments of a solid range. Heavy loads under operating conditions in the temperature range from -60C to +80C. Polyurethane products are very popular in human everyday life.