Flizelin is one of the most popular types of material in the entire sewing industry. Due to its unique properties, it is used as a lining in almost any fabric product.

Material characteristics

Flizelin is a lining material that serves as a support when sewing clothes. During the process of creating an outfit, the fabric can deform, and the seam itself can shift. To avoid this, the product is stitched from the inside with a layer of interlining, which is characterized by high strength and wear resistance.

Manufacturing

Although interlining was originally used in sewing, it is incorrect to call it fabric. In fact, it is paper, since it is produced on the basis of various types of cellulose fibers. However, unlike paper, the fibers in interlining are not arranged randomly, but according to a certain principle, after which they are pressed very tightly. In some cases, polyester fibers are added to the composition of interlining to increase strength and wear resistance.

Non-woven fabric is produced in rolls of 100 meters. The width can vary from 30 to 150 cm. The color of the material can also be very diverse.

Description of non-woven fabric

To better understand what interlining is, it is necessary to study its structure in more detail. It is based on cellulose fibers, which can be modified or unmodified, and glued or unglued. This type of material can contain reinforcing synthetic components.

In its original form, interlining intended for sewing has a milky or beige shade. The fabric acquires a different color through dyeing. The coloring can be absolutely any, it all depends on the further scope of application of the material.

Flizelin is a fabric that is used as a lining, so it has several density options. For light and weightless materials, the thinnest type of material is usually used. While coarse and thick fabrics require the use of a denser backing.

Types of non-woven fabric

Depending on the production method, there are two types of non-woven base – glued and unglued. In the first case, during the pressing of cellulose fibers, they are impregnated with a special adhesive composition. In the second case, pressing is carried out dry.

The adhesive type of interlining is divided into two subtypes. The first is a fabric in which the adhesive component is distributed over the material in a point-like manner. This method makes it possible to make the lining dense, but at the same time flexible. The second type involves applying glue over the entire surface. The result is a material with an increased level of rigidity.

Non-adhesive interlining means the absence of any impregnation. It also comes in two types - water-soluble and tear-off. The first is usually used for embroidery. With its help, the fabric does not stretch, and the threads lie more evenly. When the product is ready, it will be enough to dip it in water and in a matter of minutes the lining will dissolve like interlining paper. The tear-off type is used on the same principle, and to remove it, it is enough to simply carefully separate the lining from the base.

In addition to all of the above, there is also the so-called thread-stitched type of interlining. It is attached to the fabric by sewing along the edge.

Functions and scope of application

What is interlining used for? The main task of this material is to make the fabric more durable, protect it from abrasion, give it shape and prevent deformation. It has become a real find for a seamstress, as it has significantly simplified the process of sewing and repairing clothes. Now there is no need to put a bunch of patches, it is enough to just glue a piece of interlining to the problem area and simply sweep it up. The product will be like new.

The scope of application of this material is not limited to sewing production. Today, it is widely used for the production of various pads, packaging and coatings. It is also increasingly used in the medical field.

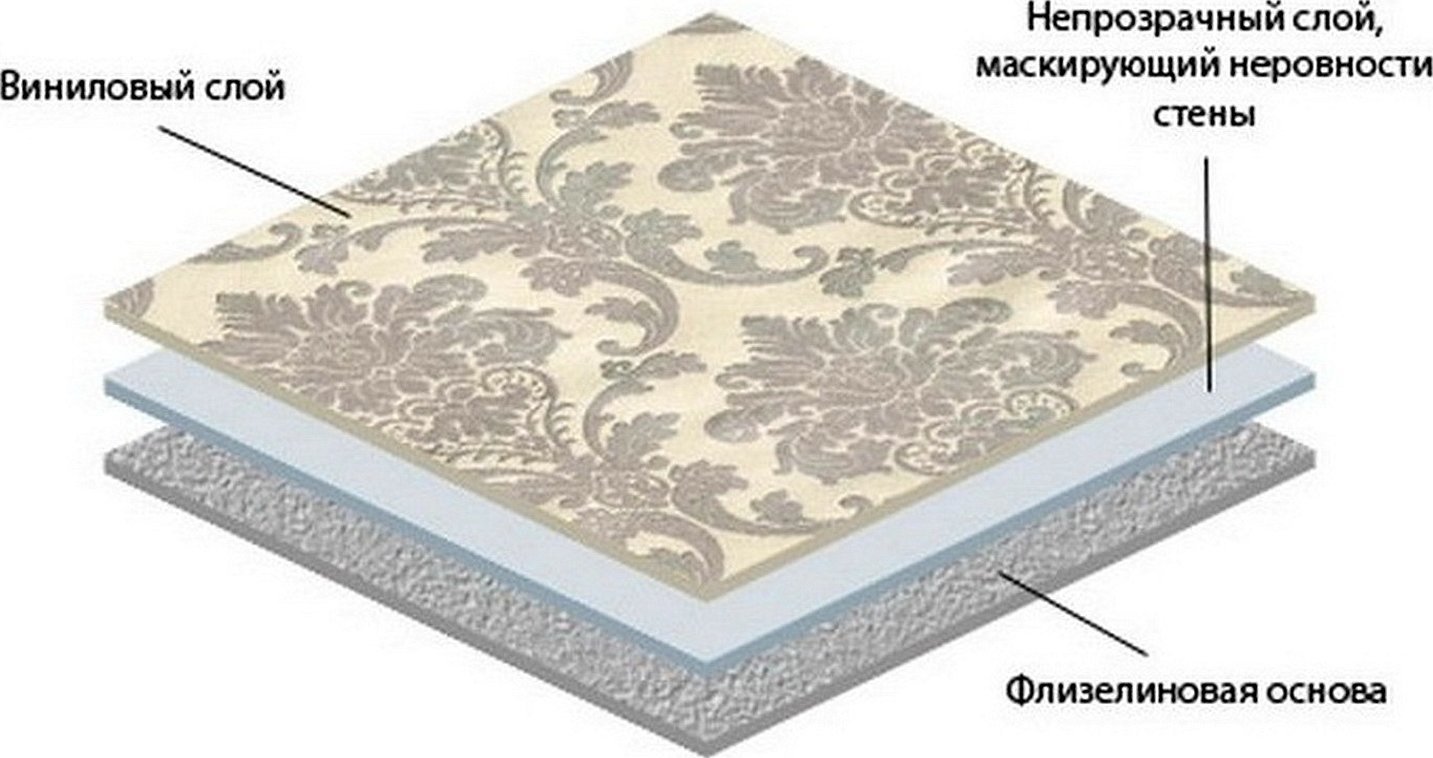

Many people wonder what kind of material non-woven fabric is when they see it in modern wallpaper. And the answer is very simple. It is the same pressed cellulose. It is used in the manufacture of non-woven wallpaper. Firstly, it strengthens the material and makes it durable. Secondly, due to its structure, when gluing, only the wall is treated with glue, and the wallpaper itself remains dry.

In addition, there is also such a thing as painter's interlining. It is a special canvas used for covering various surfaces. It is often applied to walls and ceilings to make them smooth.

Choice of fabric

The choice of non-woven backing directly depends on the fabric you are going to work with. If you can't determine by eye which type to choose, simply apply several different pieces of non-woven backing to the material and iron them. The best option will be the one on which the backing is less noticeable. If you don't want to experiment, you can simply use a special table.

The following types of base density are distinguished:

- H-180 – thickness no more than 0.35 mm. Gluing time up to 8 sec. Used with lightweight materials.

- H-200 – thickness no more than 0.32 mm. Bonding time 8 sec. Suitable for cotton and lavsan fabrics.

- H-405 – thickness up to 0.4 mm. Gluing time 8-10 sec. Used with viscose and silk.

- H-410 – thickness 0.4 mm. Drying time 10 sec. Used for all types of fabrics.

- H-420 – thickness 0.4 mm. Bonding time 10 sec. Suitable for leather, eco-leather, velour.

Important! The density of the non-woven backing must necessarily correspond to the type of fabric. Otherwise, the lining may deform the working material.

How to glue interlining

Learning all the information about interlining does not mean knowing how to use it. To avoid wrinkles and peeling, an inexperienced specialist should pay attention to the following nuances:

- Before you start gluing, you should check the serviceability and power of the iron. The heating level should be adjusted depending on the fabric being processed.

- It is necessary to glue the non-woven backing through the interlining fabric. It can be either wet or dry.

- During operation, the iron must be pressed against the surface, staying in each zone for 8-10 seconds. Do not iron the fabric under any circumstances! This may lead to deformation.

- The interlining is cut in the same way as the fabric, along the edge.

- Gluing is carried out exclusively from the reverse side of the main fabric.

- After gluing the backing, allow the material to cool completely.

By following all the above recommendations and studying in detail how to use interlining for fabric, even a beginner can handle it.

Pros and cons

Any material, even the best one, has both positive and negative qualities. The main disadvantage inherent in interlining is the likelihood of some difficulties during operation. If you do not follow all the instructions when working with such fabric, this may lead to the following problems:

- Reduced wear resistance. The reason is that the non-woven lining is not glued or covered with a protective layer of fabric.

- Deformation. Cause: improper use of the finished product. Formation of a large number of bends.

- Fragility. The reason is the poor quality of the material itself.

If we talk about the advantages, then the main advantage of interlining is nothing other than its cost. You can buy this material in any fabric store at an affordable price. Also, we cannot fail to mention its practicality. It can help out in almost any situation related to repair or sewing clothes.

Reviews

Alina, Perm

I had no idea what interlining was until I faced the problem of repairing my favorite pants. This material was recommended to me in a fabric store. It is quite easy to use, I did not need any special skills to work with it.

Valeria, Moscow

A good alternative to old lining fabrics. Really very suitable as a backing for thin materials. Often used for home repairs of clothes.

Flizelin is a universal material used in a variety of areas. It is a new trend in the big world of sewing production.