Jute is a fibre obtained from the jute plant, which grows in southern Asian regions such as Bangladesh, China, Nepal, India and Thailand. The plant belongs to the flax family of grasses and subshrubs. Although there are approximately 40 different types of jute, only two of them, short-fruited and long-fruited, are used to produce jute fibre.

Features of jute

Jute fiber is actively used for the production of insulation in the construction industry and textiles, covering various types and purposes. Its demand can be explained by excellent technical characteristics that affect the final properties of insulation.

Jute batting, which is most often used in the construction and textile industries, has a number of characteristic features:

- high resistance to decomposition - ideal characteristics for insulating wooden structures such as log cabins. Jute contains natural lignin resin, which helps increase the biostability of the fibers of this plant;

- low thermal conductivity - jute is less susceptible to blowing than flax, which significantly improves its thermal insulation qualities;

- jute batting is an economical insulation option;

- has a light weight;

- has hygroscopic properties;

- tolerates temperature changes and direct sunlight well;

- environmentally friendly material;

- antiseptic and hygienic properties;

- has a warm golden brown hue;

- easy to use.

Jute batting is free of harmful substances, foreign additives and recycled products. When it is laid, no dust is generated, it does not crumble, it has regular geometric shapes and is characterized by uniform density.

Due to its chemical composition, jute is able to absorb ultraviolet and infrared rays. This property allows maintaining a pleasant temperature regime inside the room.

Another notable feature of jute fiber is that it does not attract birds at all, unlike some insulation materials that they may use to build their nests.

Please note! In the process of jute batting production, only natural materials are used, without adding artificial elements. Wooden living quarters, baths and other buildings, in which plant thermal insulation is used, provide a comfortable internal microclimate.

Types of batting

What is batting and for what purposes is it used? What types of this material exist and what useful properties does it have? Let's take a closer look at the characteristics of this natural construction and textile material.

Wadding is a material that can be knitted or non-woven, used as insulation and for cleaning.

Wadding is made from different types of fibres, which affects its final characteristics and areas of use:

- jute is a natural plant fiber that is used in the construction and textile industries;

- Wool is a fiber obtained from animals;

- semi-wool is a combination of natural wool with cotton, viscose or polyester fibers;

- viscose is a man-made fiber based on cellulose;

- Synthetics are chemical materials made from recycled polymers;

- "shaking" is flax waste.

Wadding is practically not susceptible to dyeing, which makes it easy to determine its composition by color and appearance:

- Jute - a shade of golden brown;

- cotton – includes white, soft beige and light gray shades;

- Wadding made from waste is characterized by a combination of fibers of different colors.

Wadding fabric is a durable and versatile material. It finds its application in various industries:

- In the light industry, batting serves as insulation for coats, jackets and other winter and demi-season products, as well as for workwear. Jackets and coats usually have a reliable batting lining inside to keep warm on frosty days;

- This material is an excellent insulation for blankets. Cotton wool is almost never used in blankets; instead, batting is often used. If the question arises about what is better - batting or synthetic padding, it is worth considering that synthetic padding and cotton wool can get knocked down after washing or over time. Batting in a blanket perfectly retains its shape and, with proper care, retains its structure for a long time;

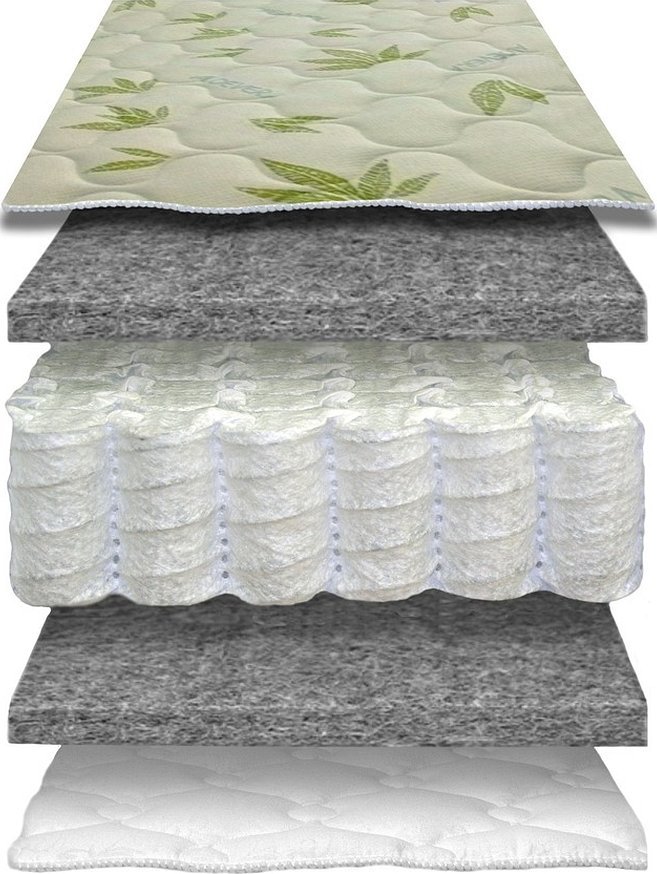

- Wadding is also used in furniture as a cushioning material in the production of mattresses, sleeping bags and upholstered furniture;

- It is used to achieve soundproofing of cars;

- Wadding fabric is used for thermal insulation and filtration;

- flax batting and jute material are widely used in construction for noise and heat insulation of residential and industrial buildings, as well as in wooden structures and for laying floors;

- Garden wadding is used to protect heat-loving plants in the country during the cold season, most often covering roses in winter.

Main use

Jute batting is mainly used as insulation between the crowns. However, its application is much more diverse. This material finds its application in furniture production, mattress manufacturing and ironing boards. To a lesser extent, it is used in sewing specialized clothing.

Jute fabric, made from fabric, is characterized by high strength and the ability to absorb moisture, which makes it an ideal material for the production of durable jute bags, eco-bags and other environmentally friendly products.

Please note! Jute has the ability to form correct geometric lines, which allows you to avoid using clapboard when finishing rooms. The insulation provides perfectly even seams, making the walls look neat, cozy and stylish.

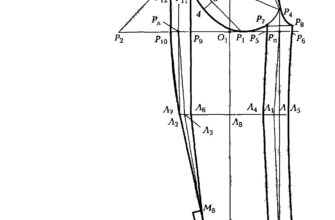

Method of laying in wooden buildings

Filling cracks with jute in a wooden log house ensures reliable insulation of the building throughout its entire service life. The process of laying the heat-insulating material requires the same attention as the construction of the log house itself. Incorrect execution of the caulking technology can lead to the house becoming cold, windy and uncomfortable for living.

Jute insulation provides optimal conditions for wood, which contributes to the durability of the structure. In addition, caulking prevents excessive moisture in the wood, protecting it from rotting, as well as from the appearance of insects, fungi and mold.

The technology of log insulation is carried out in two stages. The first laying is carried out during the construction of a log house, and the final one - after its shrinkage.

The primary caulking process is carried out in two stages. In the first stage, jute wadding is laid between the crowns during the construction of the log house. After the installation of the walls is completed, the final processing of the seams is carried out. To fill the gaps using jute tape, it is necessary to follow certain rules:

- The crowns are pre-cleaned from dust, shavings, dirt and other contaminants. The jute is glued to the wall at intervals of one meter using a construction stapler;

- The remaining tape is cut along the edge of the timber or aligned with the laying groove of the log;

- The dowels are driven through the tape. Cross-shaped cuts are made at the puncture points;

- These actions are repeated for all crowns.

The laying of caulking begins with the lower crown, using a special tool. The walls and roof must already be built. After the work is completed outside, you can begin the process inside the premises. The technology remains unchanged.

After the frame has been left to shrink, the finishing stage begins. The first layer of insulation may deform, and the gaps between the crowns become larger. In this regard, secondary caulking is carried out again. During the shrinkage process, the wood may crack, forming long and deep cracks. These cracks are filled with flax tow and sealed with a sealant.

Pros and cons

Inter-crown heat insulator made of jute is actively used in the construction industry. This is due to its reasonable price and numerous useful properties. Among the advantages of jute, the following can be highlighted:

- high concentration of lignin - a natural resin that ensures a reliable and hermetic connection of the insulation with the wooden surface;

- compliance with environmental and sanitary standards, production according to GOST. Jute is practically not subject to decay, has antibacterial properties and does not contain foreign and chemical impurities;

- durable thermal insulation. The material retains its shape and is slightly compressed due to its high rigidity;

- simple installation process that does not require special education or complex equipment. Flax is easily laid in the space between the crowns;

- wide range of applications. Jute is ideal for caulking and thermal insulation of external and internal walls, floors, windows, roofs and other structures;

- neat appearance. The caulked surface looks neat and aesthetically pleasing. The beige color of jute combines well with wood.

Despite all its positive characteristics, jute has several minor disadvantages that may affect its use as insulation:

- the service life of jute is limited. Natural material is subject to destruction over time, so the caulking should be renewed periodically;

- insufficient moisture resistance. Although jute fiber has a certain resistance to moisture, prolonged contact with water can negatively affect the thermal insulation characteristics. Experts advise laying jute batting only in dry weather with low humidity;

- The completion of the insulation installation must be carried out with finishing caulking using jute rope, which will help prevent cold air from entering the room.

Jute batting is a multifunctional thermal insulation product that is used to maintain a comfortable indoor microclimate both in wooden houses and in cars. Jute is widely used in the light and furniture industries, as well as in handicrafts. Due to its thermal insulation characteristics and environmental indicators, jute fiber can be confidently used in almost any area of human activity.