Sewing machines produced by the German company Veritas meet quality standards, are multifunctional, and are easy to use. Due to these advantages, they are always in high demand.

- Features of Veritas sewing machines

- Veritas Sewing Machine Operating Instructions

- Common Veritas Machine Breakdowns

- Upper thread breakage

- Bottom thread breakage

- Needle breakage

- Poor quality stitching

- Skipping stitches

- Poor fabric advancement

- Noise when sewing

- Possibility of DIY repairs

- How much does a repair cost in a workshop?

Features of Veritas sewing machines

This German brand released its first sewing machine in 1948. The special feature of their model was a shuttle that could rotate during operation. After some time, it was improved by adding removable feet, which increased the functionality of the machine.

In 1978, the new Veritas model became a real breakthrough in sewing machine production. This machine no longer needed constant lubrication – the process became automated. The German company continued to improve its production, and soon a new function was added – embroidery. Then the work place lighting was improved and an LCD display appeared.

Veritas manufacturers are constantly improving their models, making them even more reliable in operation. And new technologies simplify the sewing process. Sewing machines of this brand have their own features that distinguish them from others:

- Almost all models have a separate needle for working with coarse materials. For example, when sewing outerwear, jeans;

- The Veritas sewing machine makes zigzag stitches;

- the presence of a TUR-2 motor, which is known for its reliability;

- the nodal connections are made of metal, which increases the service life of the sewing machine;

- the pedal is made of metal, but the top cover is made of a rather fragile material. Therefore, if used incorrectly, it may periodically break;

- difficulties in finding machine components for repair. Production of old models was stopped in 1991, so spare parts are difficult to find. Often you have to buy the whole machine along with them, which can be quite expensive;

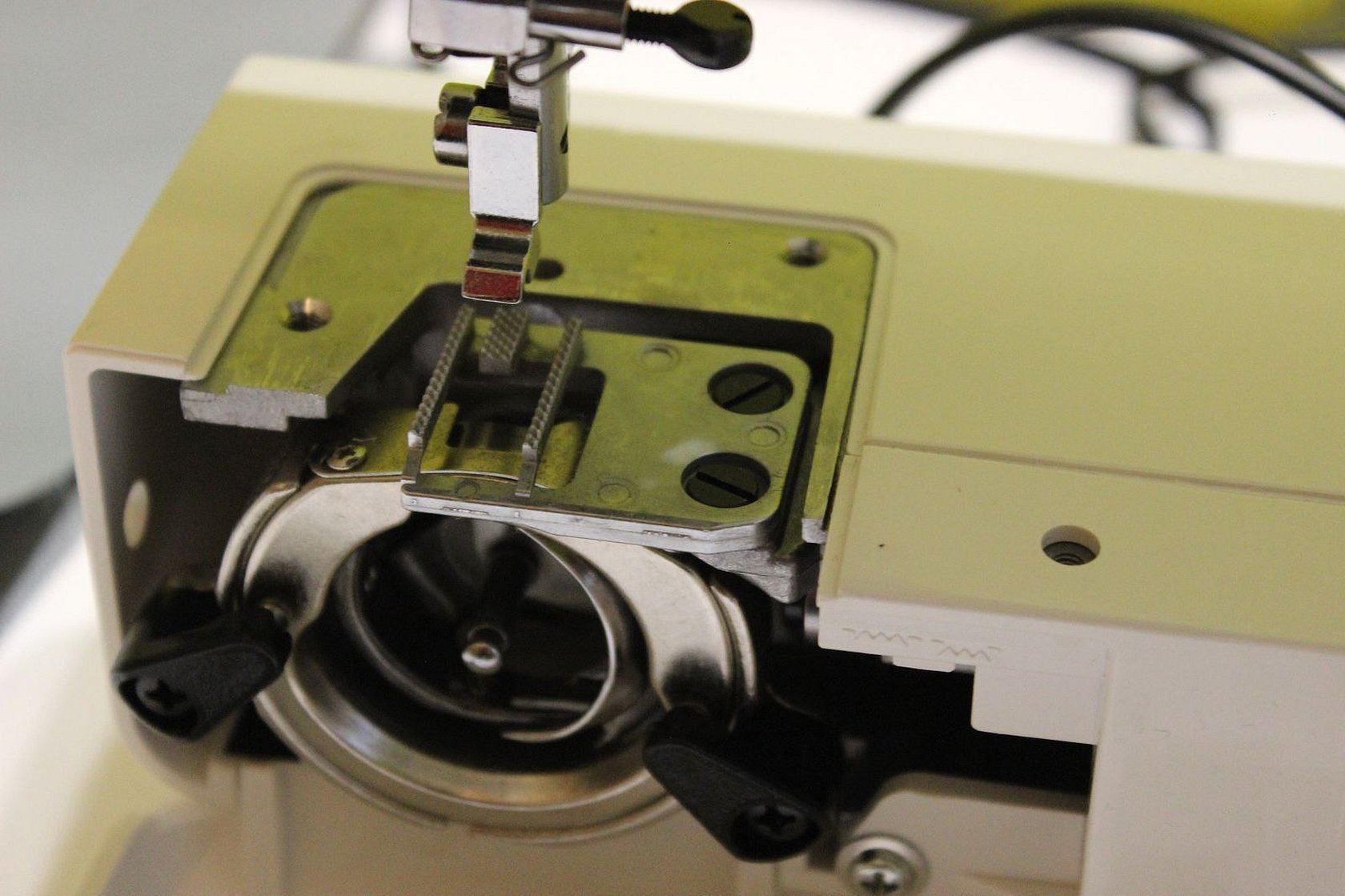

- When the thread gets into the shuttle, the entire equipment jams. To solve this problem, you have to disassemble and assemble the shuttle.

With all its advantages, Veritas products cannot compete with modern European and Asian manufacturers. Because it cannot sew complex models. Its main advantage in comparison with others is its low cost.

Veritas Sewing Machine Operating Instructions

Each sewing machine comes with an instruction manual. But since Veritas does not produce sewing machines, it is difficult to find the operating instructions. Each model has its own subtleties of use. The most popular was the sewing machine "Veritas-Rubina-1290", the instruction with the main points for working with which is given below:

- You need to turn the flywheel towards yourself.

- Before starting sewing, lower the presser foot.

- Do not turn on the sewing machine with the thread threaded if there is no material.

- Do not move the fabric while sewing.

- It is necessary to keep the machine clean and lubricate it if necessary.

- The thread feed lever should always be raised as high as possible to prevent the thread from getting pinched.

- In the idle position, you can press the buttons and levers only if the needle is above the fabric level.

If you follow the above rules, the equipment will last a long time, and the sewing process will proceed without difficulty.

Common Veritas Machine Breakdowns

Repair of broken sewing equipment should be entrusted only to professionals, because they will be able to accurately determine the cause of the malfunction and fix it. This is especially true for older models, for which it is difficult to find new components, so it is difficult to repair them.

Despite all the reliability of the German brand models, due to improper operation, a breakdown may occur. Repair of the Veritas sewing machine can be done at home if you know the cause of the malfunction.

Upper thread breakage

The most common breakdowns may be caused by the following:

- the thread was not threaded correctly in the sewing machine;

- thread of poor quality, uneven thickness and with knots;

- the thread thickness does not match the selected needle;

- too much top tension.

Sometimes the reason for the upper thread breaking is a breakdown of the sewing machine mechanism. If the thread was threaded according to all the rules, and the seamstress uses high-quality working material, then it is worth contacting a repair shop.

Bottom thread breakage

One of the reasons may be a poor quality thread or its mismatch with the working needle. But there are other factors that cause this malfunction:

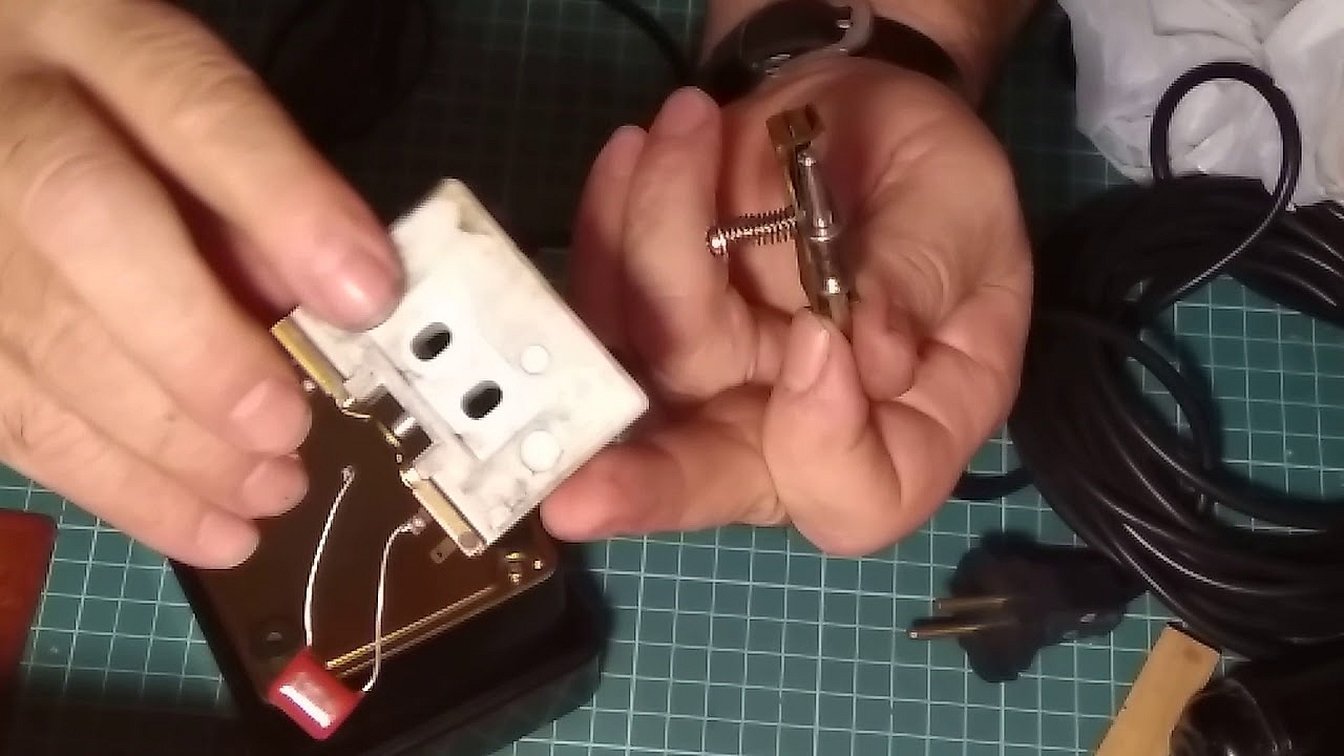

- incorrectly selected bobbin;

- the bobbin is not inserted correctly into the cap and into the shuttle;

- unadjusted lower thread tension;

- the shuttle mechanism has not been cleaned for a long time, and the resulting dirt makes it difficult for the thread to move;

- damage to the needle plate;

- loosening of the bobbin mechanism fastenings.

Some sewing machine breakdowns can be avoided if you regularly monitor its cleanliness. Therefore, before work, you should always carefully follow the recommendations set out in the operating instructions.

Needle breakage

Quite often, during the sewing process, the needle breaks due to the following reasons:

- its size does not match the fabric or working threads used for sewing. Therefore, when selecting a needle, you need to refer to the size matching table;

- deformation of the needle or its incorrect installation in the mechanism;

- needle bar deformation;

- Strong tension on the fabric during sewing can cause the needle to break.

A damaged needle must be thrown away and a new one installed that matches the parameters of the working fabric and threads.

Poor quality stitching

Sometimes when sewing, the stitching starts to loop or is uneven. This is often caused by the low quality of the threads and needle, and their inconsistency with the working fabric. The following factors can also lead to this sewing machine malfunction:

- the top or bottom are wound unevenly. To do this, use a special device;

- uneven tension of the upper or lower thread;

- contamination of the tension mechanism and shuttle compartment;

- In a sewing machine with a vertical shuttle design, the bobbin case may break as a result of prolonged operation.

These are the most common reasons why you may get a poor quality stitch.

Skipping stitches

The reason here may be a broken needle, caused by various factors. But the case may be more serious if the needle and shuttle are not working together. Only a specialist can fix this problem.

Poor fabric advancement

This difficulty in work can be caused by the following factors:

- conveyor deformation. Only a specialist can replace the rack;

- incorrect foot pressure;

- Incorrect foot installation.

Also, you cannot move the fabric during the sewing process to avoid malfunctions in the equipment.

Noise when sewing

If the machine starts making unusual sounds, you can stop working immediately. One of the most common reasons is untimely cleaning and lubrication of the mechanism parts. Or broken threads remaining in the conveyor or shuttle compartment. Then you need to carry out maintenance according to the instructions.

Other causes of noise:

- knocking of the needle against the needle hole caused by the displacement of the needle bar from its position;

- incorrect positioning of the lower conveyor;

- breakage of the shuttle leaf spring;

- The foot is set at the wrong height.

However, not all Veritas sewing machine breakdowns can be identified independently. Professionals will be able to accurately determine the malfunction and quickly fix it.

Possibility of DIY repairs

Some Veritas sewing machine malfunctions can be repaired independently. You can repair it without resorting to the services of specialists in the following cases:

- If the threads were not threaded correctly or are of poor quality.

- If the needle breaks, but the needle bar is not damaged.

- Conveyor regulation.

- Contamination of some parts of the machine.

Before you start repairing the equipment, you need to find the operating manual. If the machine is filled correctly and the malfunction remains, you should seek help from professionals.

How much does a repair cost in a workshop?

Repairing a Veritas sewing machine is difficult because of the difficulty of selecting parts. Its cost does not exceed 1,500–2,000 rubles, unlike a washing machine. Everything depends on the type of breakdown and the availability of the necessary spare parts from the repairman. To repair any sewing machine, diagnostics are carried out. In some workshops, diagnostics costs from 200 to 300 rubles, in other services it is free.

The Veritas Rubina sewing machine continues to be in demand, despite the fact that it is inferior to more modern analogues. The equipment of this German manufacturer rarely breaks down due to the high-quality materials used for its production.