The ability to hem a dress or skirt manually with a blind stitch will come in handy not only when buying a ready-made product, when you need to adjust the length, but also for those who are keen on sewing and want the clothes to be perfect. The operations described below are not at all difficult with proper preparation of tools, threads and a work area. The correct length of a dress or skirt, trousers will complete the intended image.

- Blind stitch

- Necessary inventory

- Methods of hemming a product

- Double hem

- Hemming with a cut facing

- Hemming the edge with edging

- How to correctly mark the bottom line of a garment

- Marking the bottom line according to the pattern

- Marking the Bottom Line with an Assistant

- Marking the hem line using a marking stand

- Hemming the product with a single hem

- Hemming and trimming the seam allowance

- Fixing the hem with a spider web

- Fixation with spider web on heavy fabrics

- Sealing the hem

Blind stitch

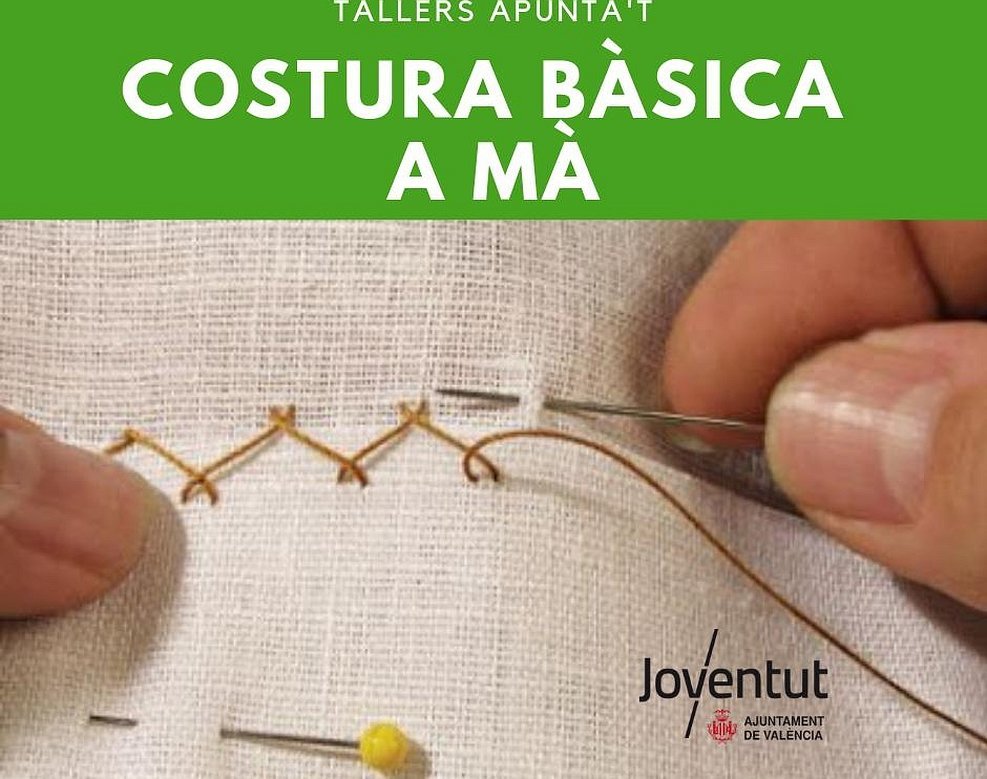

Sometimes, when hemming a dress or skirt, it is necessary to lay a decorative stitch along the hem, in accordance with the style of the product itself. But most often, when hemming the bottom of garments, especially from noble, natural fabrics, it is customary to hide the stitch connecting the hem and the main fabric.

The blind stitch is done by hand, but a sewing machine can also be used to make this seam. The seam is not visible from the front side of the product, and a seam is made from the back side, catching the thread in the needle on the thread of the main fabric.

Hand stitching, called "goat stitch", is the easiest way to hem a dress by hand with a blind stitch. You can hem knitwear by hand, like fabric, in the same way or with a stitch "over the edge". The thread tension is also done manually. The needle catches the thread of the fabric below the fold with a seam back, is brought forward and catches the thread of the fold also with a seam back. This "rapport" is repeated along the entire length of the product, attaching the fold to the main fabric. How to hem knitwear by hand

The threads should be selected so that the thickness of the hem thread matches the thickness of the fabric thread, and the hidden stitches do not stick out or pull the fabric. This way the stitching will be invisible and the surface will be absolutely smooth on the front side.

Necessary inventory

To create a blind stitch manually, use:

- Sewing thread,

- Sewing needle,

- Thimble,

- Chalk or a thin piece of soap,

- A ruler or a template,

- Iron.

The thread must match the thickness of the fabric. Thick fabrics, wool, suiting are not hemmed with thin threads. For hemming silk, satin, crepe de chine, thin threads of the same composition are used. The same applies to needles, thick needles are used for thick fabrics, medium ones for suiting, thin ones for silk, chintz.

For manual work, use a thimble, which will help protect your fingers from punctures and make working with a needle easier.

Chalk or soap is needed to draw the fold lines of the fabric. To get a clear and thin line of the future fold, it is necessary to sharpen the edges of the soap or chalk.

Important! When steaming or ironing, the soap will completely disappear from the fabric under the influence of steam. It is better to use soap without fragrances. Chalk will need to be additionally cleaned.

When sewing a product with a machine, special feet or separate attachments for a standard foot are used. The task of the attachment is to prevent the needle from catching excess threads on the front side.

Blind stitch feet are included with sewing machines, and their operation is described in detail in the operating instructions.

Methods of hemming a product

There are several simple and popular ways to process the bottom of clothes, including how to hem a skirt with a blind stitch by hand. Each of the methods is used when working with certain fabrics, styles and forms the hem of the product.

Please note! It is recommended to make trial samples if possible, make changes if necessary and only then proceed to processing the bottom of the product.

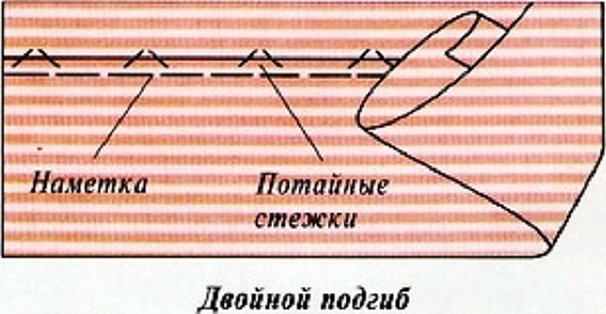

Double hem

Double hem as a variant of bottom processing is performed with a closed seam at the fold, which gives the product a neat appearance from the inside. It is used when working with fabrics of different density and weave, from thin to suit fabrics.

- The front side of the bottom of the product is turned to the back side by 1-2 cm and ironed.

- The fold is turned back to the wrong side again by the amount of the hem, from 3 to 7 cm depending on the style, cut and other parameters, and ironed.

Next, it is stitched with a blind stitch or manually using a “goat” stitch.

Hemming with a cut facing

The cut facing completely repeats the curves of the product and makes it possible to create unique models. These can be neckline cutouts, armholes, slits along the bottom. Open seams are processed with a cut facing.

The facing is cut out, exactly repeating the cut that will be processed. It is sewn to the cuts with a machine. Then the facing is turned to the wrong side and sewn by hand with a blind stitch.

Hemming the edge with edging

Original models with edging tape trim or with the possibility of wearing on both sides are processed by edging the edge. The edging tape or cut strip of fabric is folded with the wrong side inward and ironed. The front side of the tape or strip is applied to the front side of the product so that the open edges are on one side. The tape is stitched and turned down and to the wrong side. From the wrong side, the open edge is folded under and manually stitched with a blind stitch.

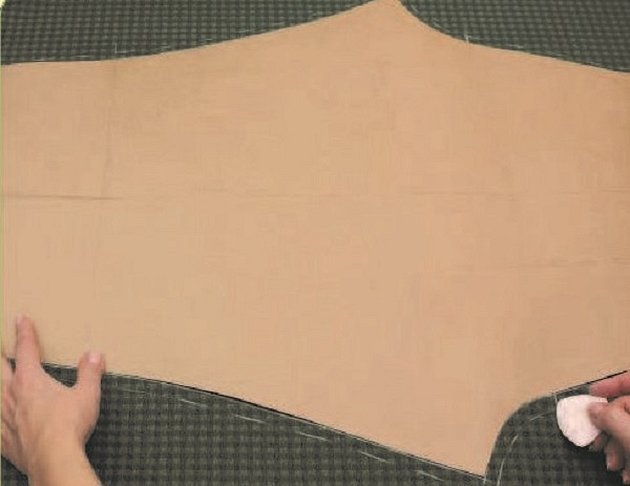

How to correctly mark the bottom line of a garment

Before marking the bottom line of a product with a free pattern, preliminary preparation for this operation is necessary. The product should be ironed well, the length should be determined, and the shoes should be prepared. The length is determined by measuring the segment from the floor to the bottom of the product. The segment should be the same length. A mark is applied to the fabric, and the marks will subsequently be connected into a single fold line.

Important! A skirt, dress or robe cut on the bias requires special care when preparing for measurements. Seams and darts should be perfectly ironed. Check the side seams for slant.

Checkered fabric requires a different approach: when cutting, you should take into account the size of the check, its “rapport” and decide on the length.

Marking the bottom line according to the pattern

An easier way to draw the bottom line is to draw the pattern lines on the fabric with chalk. Turn the fabric along this line to the wrong side, baste and iron. Try on the product and adjust the length if necessary.

Marking the Bottom Line with an Assistant

In order to mark the bottom line on the finished product, you can involve an assistant who will measure the distance from the floor to the hem of the product with a ruler, marking it with pins. After that, fold the hem to the wrong side and sew it to the dress, skirt. If you need to hem a floor-length dress, then how to do it correctly is described above. The method will be the same.

Marking the hem line using a marking stand

If there is no assistant, use a technical device: a stand with a chalk sprayer. After putting on the finished product and setting the desired length on the stand, you need to evenly rotate around yourself and simultaneously squeeze the sprayer to spray the chalk. A chalk line will appear on the fabric, along which you can form the hem of the bottom of the product.

Hemming the product with a single hem

When hemming an item made of thick fabrics, the hem is made single so as not to create excess thickness. Such hem cuts are not processed, and on suit fabrics the cut is overcast.

Hemming and trimming the seam allowance

To achieve a particularly smooth appearance on the front side, when sewing the hem, cut off the excess parts of all seams in the places where the hem will be sewn. For the best fit of the hem, a line is laid along it. The line must be gathered for freedom of position at the seam.

Fixing the hem with a spider web

The adhesive tape in the form of a spider web makes it easier to form the bottom of the garment. The tape is placed inside the hem, as close to the cut as possible. The cut must be processed. The hem is ironed with an iron heated to a temperature corresponding to the type of fabric. The hem is fixed with pins or thread.

Important! Do not iron the adhesive tape several times. Overheating the tape will cause deformation of the fabric and the hemline.

Fixation with spider web on heavy fabrics

The major difference when using fusible webbing on heavy fabrics is that the webbing must cover the entire width of the hem for a better hold.

Advice! Fixing the iron on the hem and slightly moistening it will result in a better quality connection with the adhesive tape of the hem to the main fabric. Ironing in this case will not help in achieving the result.

Sealing the hem

Suit and dress fabrics in the hem area are reinforced with a duplicating fabric to achieve an ideal smooth surface on the front side. To do this, the duplicating fabric is secured on the back side of the product along the fold line of the hem. The hem is turned to the back side and hemmed.

Using the above techniques, you can neatly design the bottom of the finished product. The final sewing operation creates the final appearance, emphasizes the style and forms the image. Correctly selected threads and tools will help to perform this work efficiently.