Hand embroidery is one of the ancient traditions of ancient Russia. It has many different artistic types and can be a real work of art. In the past, girls were always taught housework and needlework, since a real woman had to master these skills and pass them on to her children. Today, this type of needlework is back in fashion, it is used not only as a hobby, but also as a means of earning a good income.

- From ancient times to the present day

- What types of embroidery machines are there?

- Auxiliary devices

- How to choose the type of machine for yourself

- How to make an embroidery machine with your own hands and how to choose a good ready-made machine

- How to make a machine for embroidery with your own hands

- Tools for making a sofa machine

- Consumables for making a sofa machine

- The process of manufacturing machine parts

- We make horizontal legs

- Manufacturing of round guides

- Assembling the machine into a single unit

- Machine settings

- How to embroider on a machine with two hands

From ancient times to the present day

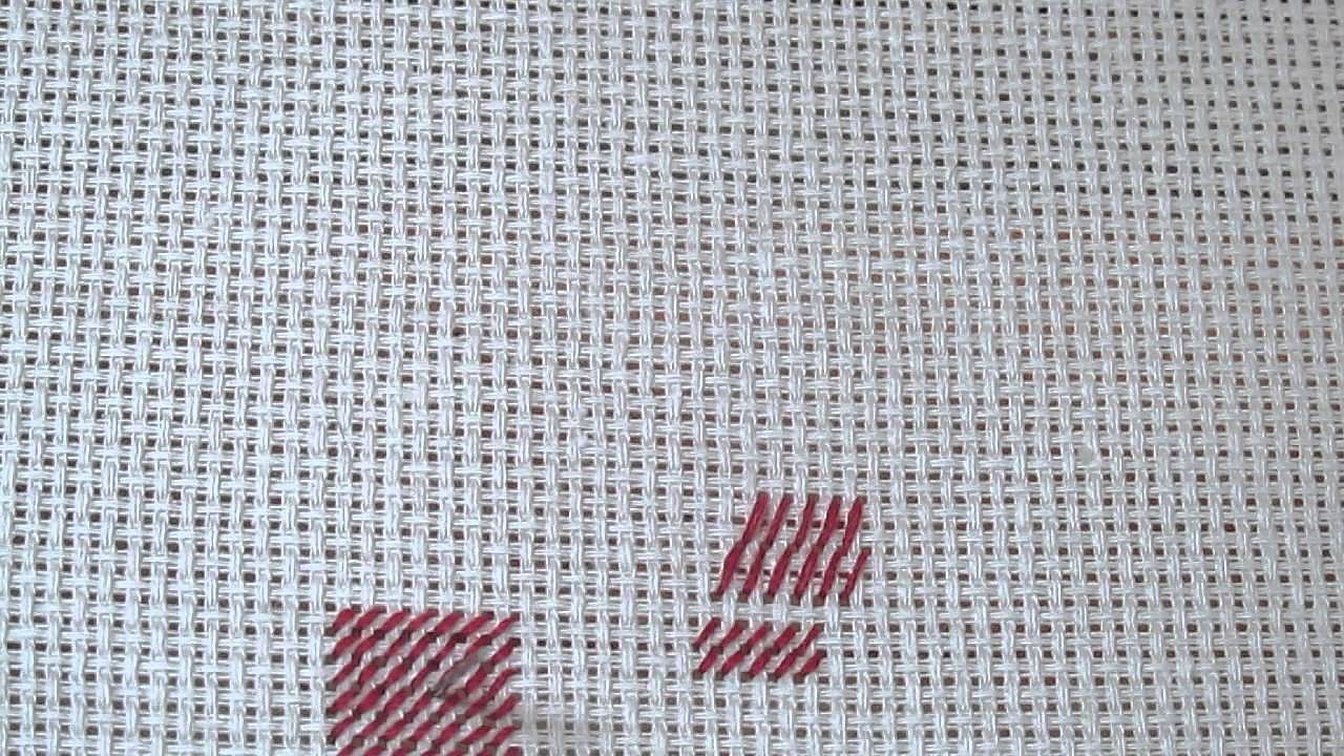

Artistic embroidery has been a women's craft and a useful skill since ancient times. Certain rules and styles were passed down from older to younger generations, and that is why no two identical works were found, which was of great value. For small items, hoops of various shapes were used, and large items were made using homemade or purchased embroidery machines.

Machine embroidery is in great demand in decorating modern things. However, just as restaurant dishes cannot be compared to home cooking, so self-made embroidery will never be inferior to factory-made. Quite recently, this type of handicraft has become fashionable again among people with creative inclinations. Gradually, sewing and embroidery began to take on new development turns, impressing people with emerging techniques and trends. At the moment, decoration with ribbons, beads and gold threads is especially popular.

What types of embroidery machines are there?

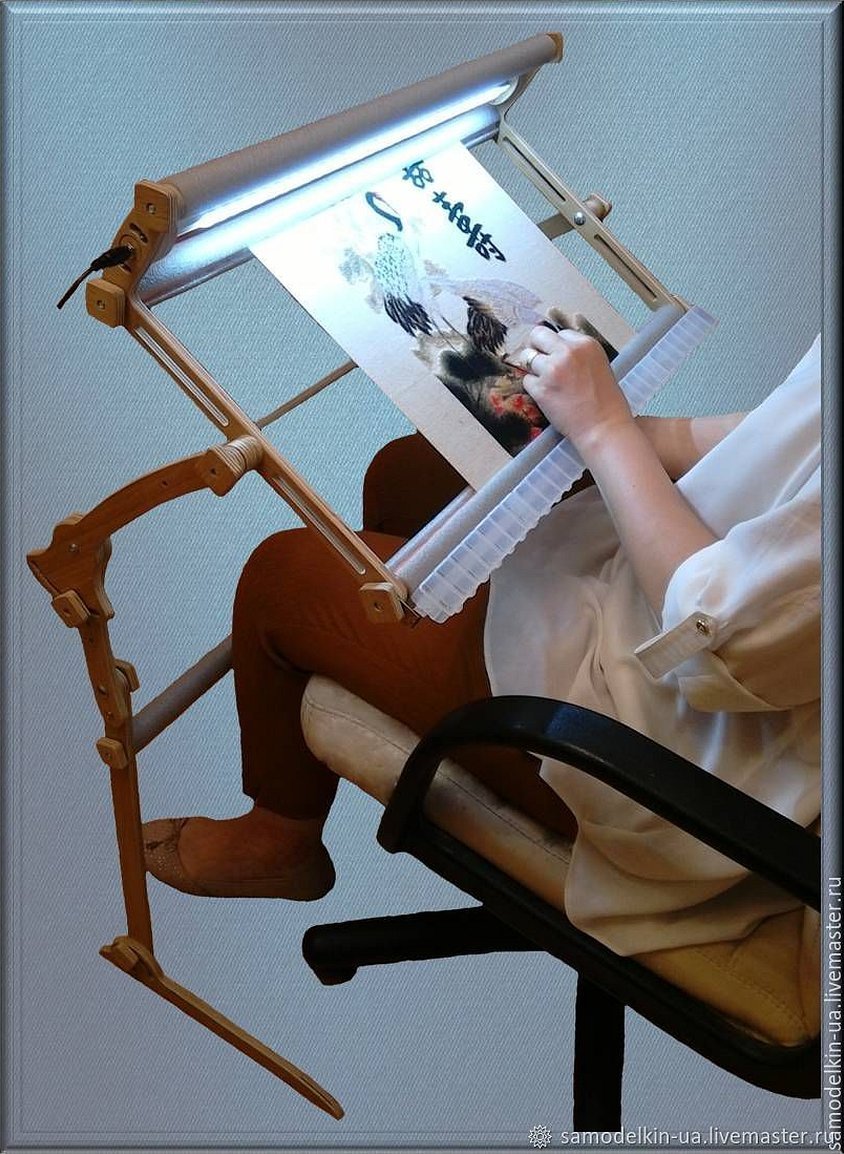

The main function of the embroidery machine is to free the hands of the craftswoman, which significantly accelerates the work process. In addition, a high-quality machine ensures not only a comfortable position for the material, but also for the person himself. The design of the device actually consists of holders and a frame, but according to the place of use, it can be divided into the following types:

- Sofa embroidery machine. It is used when it is most comfortable to work on a sofa or bed. This allows the body to rest, because not every craftswoman can stand for hours in tension at work. It is often recommended to use a unit with available side holders, which allow you to adjust it precisely to the parameters of the figure and sofa.

- Sofa-table. This type of unit should be considered by those whose favorite workplace is a table. The machine can be made with a stand or on clamps that are attached to the top of the table.

- Floor version. The above units take up little space, are compact and are suitable for small canvases. But in the case when it is necessary to embroider large-sized products, the optimal choice will be a floor machine. It also requires only a small area of free space.

Important! Each person will find their own machine. Some people like to work only standing, while others prefer to work sitting due to old age or health problems.

Auxiliary devices

For comfortable work, you can place the necessary accessories for needlework on the machine. Among them may be: a needle case, a container for threads, a lamp, a magnifying glass, an organizer for markers and thread scraps, as well as a place for a diagram. All these devices are sold in a regular sewing or specialized embroidery store. Sometimes they come in sets with expensive machines.

Important! A lamp or magnifying glass attached to the unit may weigh it down, especially if it is not in a stable position. This is often the cause of the unit falling and damaging the work.

How to choose the type of machine for yourself

Masters who embroider large canvases need to select tabletop machines, sitting at which will not cause strong tension in the back, arms and legs. Such a design can be adjusted in almost all directions, which contributes to a comfortable position of the canvas and body. Devices equipped with magnifying glasses allow you to embroider on black canvas or fabric, combine non-contrasting tones, carefully check the quality of the work and make clearer stitches.

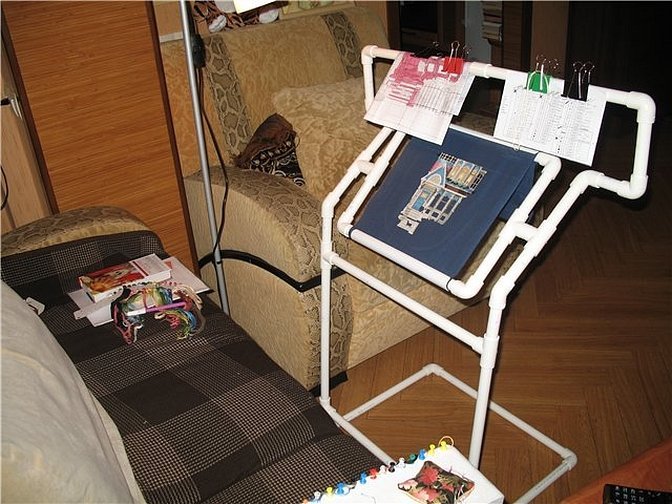

For those who are just starting to engage in creativity, the simplest machine made of plastic will do just fine. You can make it yourself using a drawing from plastic pipes.

How to make an embroidery machine with your own hands and how to choose a good ready-made machine

People who devote themselves entirely to embroidery know that the choice of equipment must be taken quite seriously.

Important! The convenient position of the cross stitch or bead embroidery pattern affects the quality of the final result and the speed of work. These are the points you need to remember when making your own machine.

Many manufacturers of hand embroidery equipment have a large range of products of various types in their assortment. It includes not only the basic designs, but also some devices that increase the comfort of work. It is worth considering a couple of popular companies producing embroidery machines that are in high demand among people, namely:

- Dubko factory. This is a domestic manufacturer that produces 20% of all machine tools in Russia. The company makes designs according to all requirements and uses only hardwoods;

- "Arabesque". Produces large-sized floor and sofa-floor machines that cope well with large-scale work.

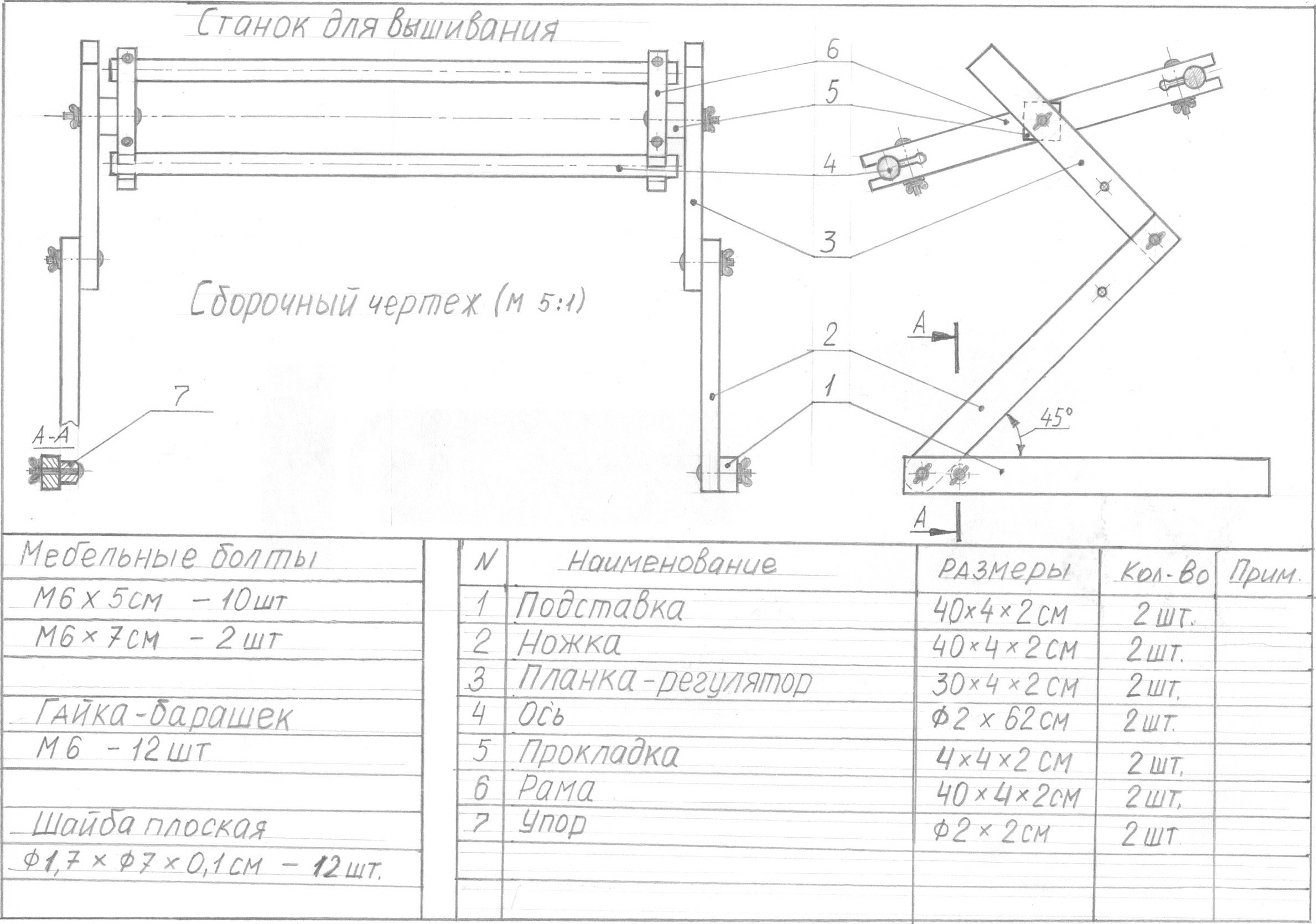

However, despite the variety of ready-made models, many still prefer to make machines with their own hands, since the work process is quite simple and exciting. Still, in order to make a sofa machine for embroidery, it is necessary to strictly observe all the parameters and focus on the drawings available on the Internet.

How to make a machine for embroidery with your own hands

The sofa-table machine is a convenient tool for everyday embroidery of small and large items. It allows you to ease the load on all parts of the body, as well as significantly speed up the work process, since you can embroider with both hands at once.

Tools for making a sofa machine

As many know, no design can be made without the use of special tools. The following list of accessories will allow you to prepare the material before starting the main work:

- jigsaw for wood;

- drill or hand drill;

- stapler for decoration.

Consumables for making a sofa machine

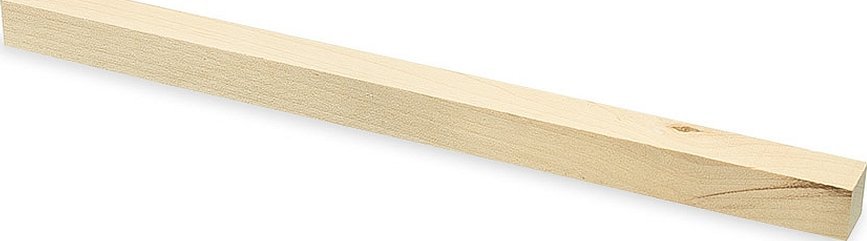

- Wooden slats.

- A round wooden stick.

- Lambs.

- Washers.

- Threaded screw (M5 and M6).

Important! It is recommended to use only hardwood as a material, as it is a durable and environmentally friendly material.

The process of manufacturing machine parts

Having learned about the necessary materials and tools, some will think that the manufacture of such equipment will be difficult and time-consuming. And yet, when a person starts working, it will immediately become clear how easy it is to build this structure using a ready-made scheme.

We make horizontal legs

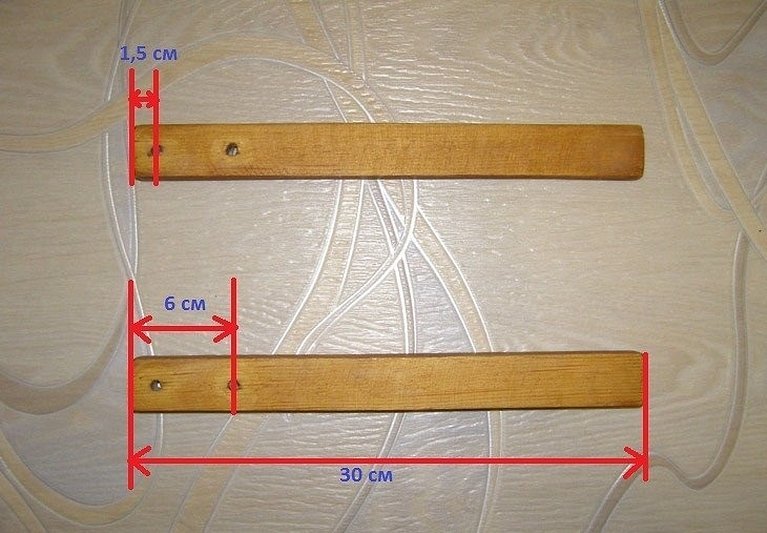

To make the legs, follow the step-by-step instructions:

- cut 2 pieces of 30 cm in size from the strip and drill two holes, one of which is 1.5 cm from the edge, and the other is 6 cm;

- make 4 more of these pieces, each 30 centimeters in size, and drill holes at a distance of 1.5 centimeters from the first and second edges;

- using a planed strip, make identical parts, but with a hole in the center (15 centimeters from the edge);

- for the side holes you need to use an M6 screw, and for the central one - an M5 screw;

- connect the legs together and make a connecting bar, the dimensions of which depend on the expected width of the panels used;

- attach a threaded M5 screw, at least 8–10 centimeters long, to the connecting rail.

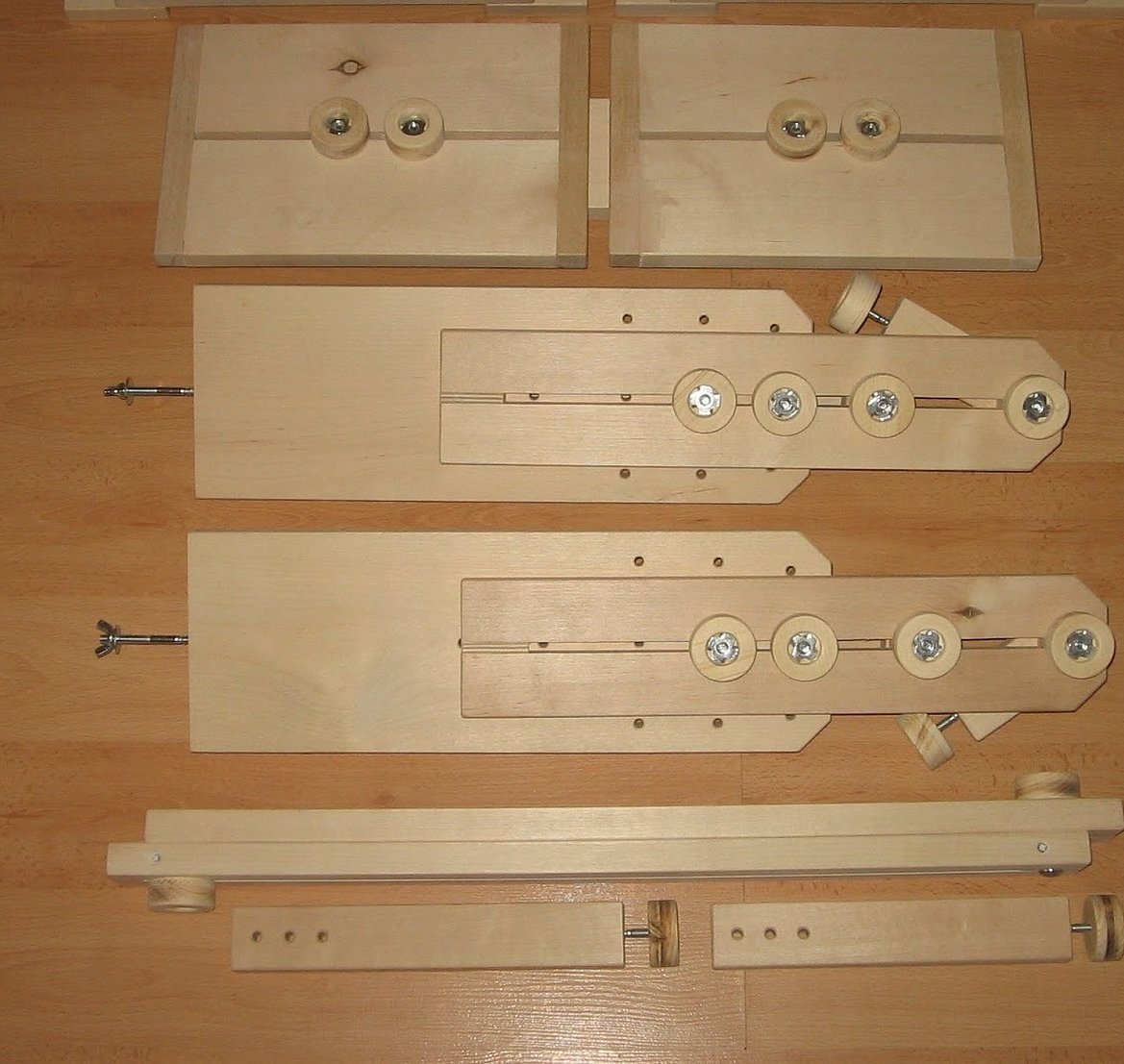

Manufacturing of round guides

Round guides are made according to the following instructions:

- cut bars measuring 45 centimeters;

- cover them with thick fabric covers, which can be secured with a stapler;

- screw in screws about eight centimeters in size on the sides of the rail.

Assembling the machine into a single unit

Before starting work, you should assemble the machine:

- take two blanks of legs with two holes and screw cylindrical parts into the far holes;

- attach a strip with two holes at the edges to the previous part of the structure;

- connect the legs with a long strip and secure them with the wing nuts;

- Insert screws into the remaining holes and secure them with washers and wing nuts.

Machine settings

In order for the master to be in comfortable conditions when embroidering, the machine should be set up correctly. To do this, take the most comfortable body position and adjust the device so that it matches it. This will determine the parameters that will be used in the future.

Important! If desired, these "settings" can be changed. The main thing is that the unit is able to rotate and turn at certain angles.

How to embroider on a machine with two hands

This style implies equal participation of both hands in the process of work and in embroidering each stitch. Both the left and right hands should move together, performing alternate monosyllabic actions. It is important to understand that each hand should have its own working area relative to the plane of the canvas.

A variant of two-handed embroidery can be as follows: one hand works from above, that is, on the front side, and the other performs similar movements from below (from the surface of the back side). You need to be sufficiently trained, since all processes from the back side are performed blindly.

Thus, an embroidery machine is a very useful thing. It is irreplaceable when creating very small or large canvases, as well as in works that require increased evenness of stitches. All this is possible due to the possibility of its adjustment.