Artificial acetate fibers are one of the varieties of unnatural threads that are obtained from acetyl cellulose. This is a successful symbiosis of natural material and chemical reagents, unlike synthetics from chemical compositions based on natural wood. All fashionistas of the mid-20s were in love with this fabric and currently modified popular types are being created.

- History of Acetate Fiber Production

- Manufacturing process

- How does molding happen?

- Microscopic structure of fiber

- Basic properties of fibers

- Some information about color

- Scope of application of acetate fabrics

- Features of care

- Washing Acetate Silk

- Drying

- Ironing

- Positive qualities

- How to distinguish acetate from other fabrics

History of Acetate Fiber Production

What is acetate? In the second decade of the 20th century, the production of acetate silk was mastered from acetyl cellulose. Later, a method was discovered for obtaining a material of greater strength from purified wood cellulose and cotton fluff.

For reference: acetates are esters and salts of acetic acid, found in nature and are common components of body cells. The most widespread are: in medicine for the production of synthetic retinol (vitamin A) and tocopherol (vitamin E); in the food industry (preservative); in textile production, acetate is a fabric or thread made of acetyl cellulose.

For the first time, elegant shining fibers were produced at the Dreyfus brothers' factory in England. The finishing was done with acetic acid salts, and they were intended for covering fuselages and wings of airplanes. Due to their high hydrophobicity, they were used as insulating materials. In 1918, this company improved the technology and began to obtain threads in the form of shining synthetic silk.

Interesting to know! Non-natural silk does not belong to synthetics. For example, acrylic and acetate are completely different materials. Polyacrylonitrile is a pure synthetic, produced from a chemical mixture of acetylene and hydrocyanic acid. Acetate is produced from natural raw materials, although artificially.

Based on this discovery, various studies immediately began. The question: what is acetate? interested many enterprises. The threads began to be used in various fields: to create insulating materials; waterproof coatings; to supplement natural silk to increase wear resistance and subsequently began to create full-fledged acetate fabrics, as identical as possible to natural silk.

Manufacturing process

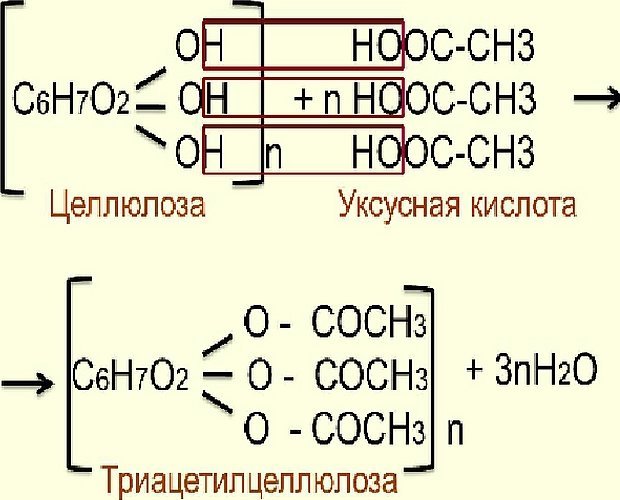

What is acetate silk? 98% of cellulose is used to obtain acetyl cellulose (primary acetate). It is produced at a temperature of 15 C by the method of substitution of hydrogen atoms. Acetic and sulfuric acids are used for this. The chemical formula is [C6H7O2(OH)3-x(OCH3)x]n. The original composition is intended for extracting fibers.

This method is used to obtain acetate silk:

- Acetyl cellulose is subjected to partial saponification, with the addition of water, during which fragments of acetyl groups are split off;

- sulfuric acid is used as a reaction accelerator;

- the resulting diacetyl cellulose is called secondary acetate (includes 52-56% of bound ethanoic acid). It has a fibrous structure and precipitates from the composition in the form of white powder or flakes;

- The secondary acetate is pressed, washed in water, stabilized (boiled with sulfuric acid) and dried.

Additional information! Triacetate is a type of acetate fiber that is produced in a solution of alcohol and methylene chloride. It has high heat-resistant properties and can withstand temperatures up to 180 °C.

Acetyl cellulose is dissolved in acetone and alcohol (85:15). The output is a thick composition from which, after removing air bubbles and washing three times, fibers are formed. They harden when the solvent evaporates and are used to form matter. Modifying additives that increase the quality of the thread.

How does molding happen?

Using the dry method, spinning takes place in the shaft:

- Acetyl cellulose is forced into a spinning machine with hot air (600–700 C), and the spinning takes place at a speed of 300–350 m/min.

- To give the threads a crimped shape, they are passed through a crimping machine.

- At the exit from the mine, the fibers are coated with a special compound to prevent electrification and wound into a bobbin.

The resulting threads do not require drying or additional finishing. Immediately after twisting and rewinding, they are directly sent to textile processing. The fiber is used as an independent material, as well as in combination with other textile threads (wool, silk). The scheme for obtaining acetate tow for tobacco is close to the production of threads; the peculiarity of the process is that a tow is obtained with the thickness of one cigarette.

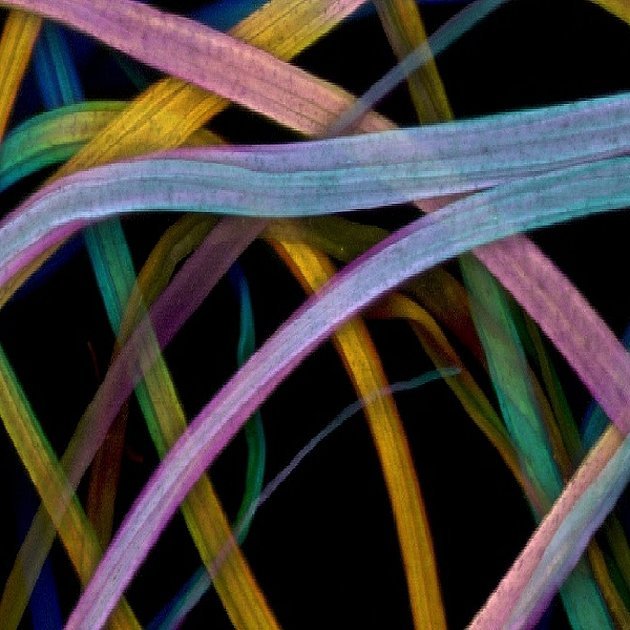

Microscopic structure of fiber

The fibers have a high-molecular structure, and the surface of the threads has small longitudinal grooves. For better adhesion, square or H-shaped transverse cuts are made. They provide strong, stretchable seams with good coverage. In addition to high strength, the fabric is characterized by a shiny shine.

Basic properties of fibers

What kind of material is acetate? These fibers are resistant to chlorine, white spirit and higher alcohols. In lower alcohols they swell slightly and collapse in mineral alkalis.

Quality and physical characteristics of the thread:

- density - 8.3-11.1 tex;

- strength - 10-14 cN/tex;

- elongation - 20-40%;

- elasticity - 3-4 GPa.

Important! Acetate fiber is completely destroyed at 1400 C.

Artificial silk threads are not affected by bacteria and insects, are slightly hygroscopic and do not wrinkle, wear out quickly and become electrified. They are more elastic than copper-ammonia and other types. A cord with a cross-section of 1 cm² can withstand a load of 10 tons. When heat treated, acetate fiber products can form creases and folds.

Some information about color

Dyeing of acetate fabrics is done with special disperse dyes, which are not suitable for many other fabrics:

- Basic - with acetic acid (1-2%). In the process, gradually increasing the temperature to 70. A common disadvantage of basic dyes is poor lightfastness.

- Dispersed - with the addition of cold solutions of copper sulfate, they give deep tones with optimal stability to light.

- Polymethine (cationic) - salts of strong bases. Certain polymethine dyes are intermediate compounds, insoluble in water, and can be used as pigments for dispersed. They give bright and clear lightfast colors.

Combining these methods makes it possible to obtain various color effects on products.

Scope of application of acetate fabrics

Silk fabric made from acetate fibers is in great demand among buyers and has a wide range of applications:

- for the production of light clothing - blouses, dresses, underwear, T-shirts;

- for drapery of furniture, production of bed linen sets, curtains;

- for the production of cigarette filters;

- as an insulating material in electrical engineering (properties similar to divinyl rubber).

Please note! Shiny and durable acetate threads are present in many materials (wool, gabardine, velvet), significantly improving the properties of products.

Features of care

Raw materials made from acetate fiber have a slippery surface. Such fabrics do not wrinkle, do not collect dust and are rarely dirty. If you follow the rules on the label, things will last a long time.

Washing Acetate Silk

You can wash acetate by hand or at low speed in a washing machine:

- Fabrics are wrung out by hand and cannot be spun in a centrifuge.

- A light solution of hydrogen peroxide will give the fabric a fresh look.

- Detergents are mild, and the short washing temperature is no more than 30° C.

- Multi-colored fabrics are not soaked.

- Dry cleaning is also possible.

Attention! Acetone or organic solvents such as nail polish remover, turpentine, will dissolve acetate fabrics.

Drying

This material dries quickly in the open air and mechanical drying of clothes is not applicable to it. In order to avoid creases in the fabric, it should be straightened well.

Ironing

Smoothing out creases is done at a low temperature — up to 160° C, from the inside of the product, through gauze or a fabric lining. It is not recommended to pull the fibers, they can break. With proper care, the material does not need ironing.

Please note! At t° above 170° C, the shape of the thread changes; at t° - 210° C, thermal decomposition of the compounds occurs.

Positive qualities

Acetate is one of the few synthetic materials of natural origin that contains viscose.

Its characteristic features are:

- the surface is shiny, smooth, soft, pleasant to the touch;

- water-repellent structure and low thermal conductivity;

- resistance to bacteria, mold and solar radiation;

- stability - products do not shrink, are elastic and maintain their shape;

- does not lose strength when wet;

- Easy to clean and dries instantly.

Please note! The light and thinnest material has many positive characteristics: it is easy to dye, gracefully draped, which provides a wide field of activity for artists, designers and fashion designers.

How to distinguish acetate from other fabrics

In order not to confuse artificial acetate fibers and synthetic threads (nylon), you can use simple methods. In appearance, acetate is almost indistinguishable from natural.

It is possible to establish the origin of matter in the following ways:

- Set on fire - unnatural modifications will create an unpleasant sour smell and roll into a ball. Natural materials, when burning, have a smell of burnt hair and quickly turn to ash.

- Apply to skin - acetate fabrics will feel cool, while natural fabrics will quickly warm up.

- To the touch, artificial silk is rougher and not as elastic and light as natural silk, while nylon has an even more rigid adhesion of threads.

- Crush or squeeze - real silk will straighten out without leaving any marks, acetate will wrinkle a little, nylon will make a characteristic crackling sound.

- Drop tests - synthesized polymers (nylon) are dissolved by acid, artificial silk - by acetone.

The progressive world of textiles cannot do without chemistry. Silk products made of acetate fiber differ favorably from others in their low price, variety and beauty. They have excellent performance properties and interestingly emphasize any design and slim figure.