In the composition of clothing, you can often see additives such as "nylon" or "elastane". These and some other fibers are also called polyamide. Polyamide - what is it and are such additives safe for natural fabrics?

Historical background

Polyamide - what is it and how did it appear? The material polyamide was obtained by Harbordt in 1862. This was a real discovery, and today this material is everywhere, and it is produced annually in quantities exceeding tens of tons. Among high polymers in industry, polyamide ranks first.

The materials in which polyamide fiber is used are quite diverse. They are used in the production of textiles (household and technical), films, and casting.

The first polyamide was obtained as a result of the reaction of m-aminobenzoic acid and hydrogen chloride. At a temperature of 200 degrees, a powder was formed that did not dissolve in most acids, as well as in alkalis. This is how poly-m-benzamide appeared - the first synthetic polyamide.

Experiments on the material did not end there. In 1881, Michler and Zimmerman obtained polyphenylene urea by saturating a solution of m-phenylenediamine in chloroform with phosgene. And in 1888, polyamides were obtained as a result of polycondensation of esters of a-amino acids. The experiment was carried out by Curtius and Hebel.

In 1935, Carothers obtained polyhexamethylene adipamide. The polycondensation reaction of hexamethylene diamine with adipic acid gave this result. As a result, the first synthetic fibers were obtained from this polyamide. Carothers initiated active research into polyamides, their creation and application. He showed that strong fibers can be obtained from molten resin by various effects (melting) on it.

Polyhexamethylene adipamide was then mass-produced (in the USA, 1938) into a material that was called nylon and became the first fabric. Polyamide fabric - what is it? It would later become one of the most famous, and its production would amount to several tons annually.

In Germany, the production of nylon fiber began in 1939. Only after some time did it begin to be produced in other parts of the world.

Polyamide - what kind of material is it? It is a high-molecular compound with a molecular weight of up to 30,000. The molecules are flexible methylene chains with polar amide groups located along them. The presence of such groups is capable of synthesizing hydrogen bonds and this helps to determine the chemical properties characteristic of all such materials.

However, despite its origin, polyamide has some similarities with natural fabrics. For example, to the touch such synthetics will be like cotton.

Production technology

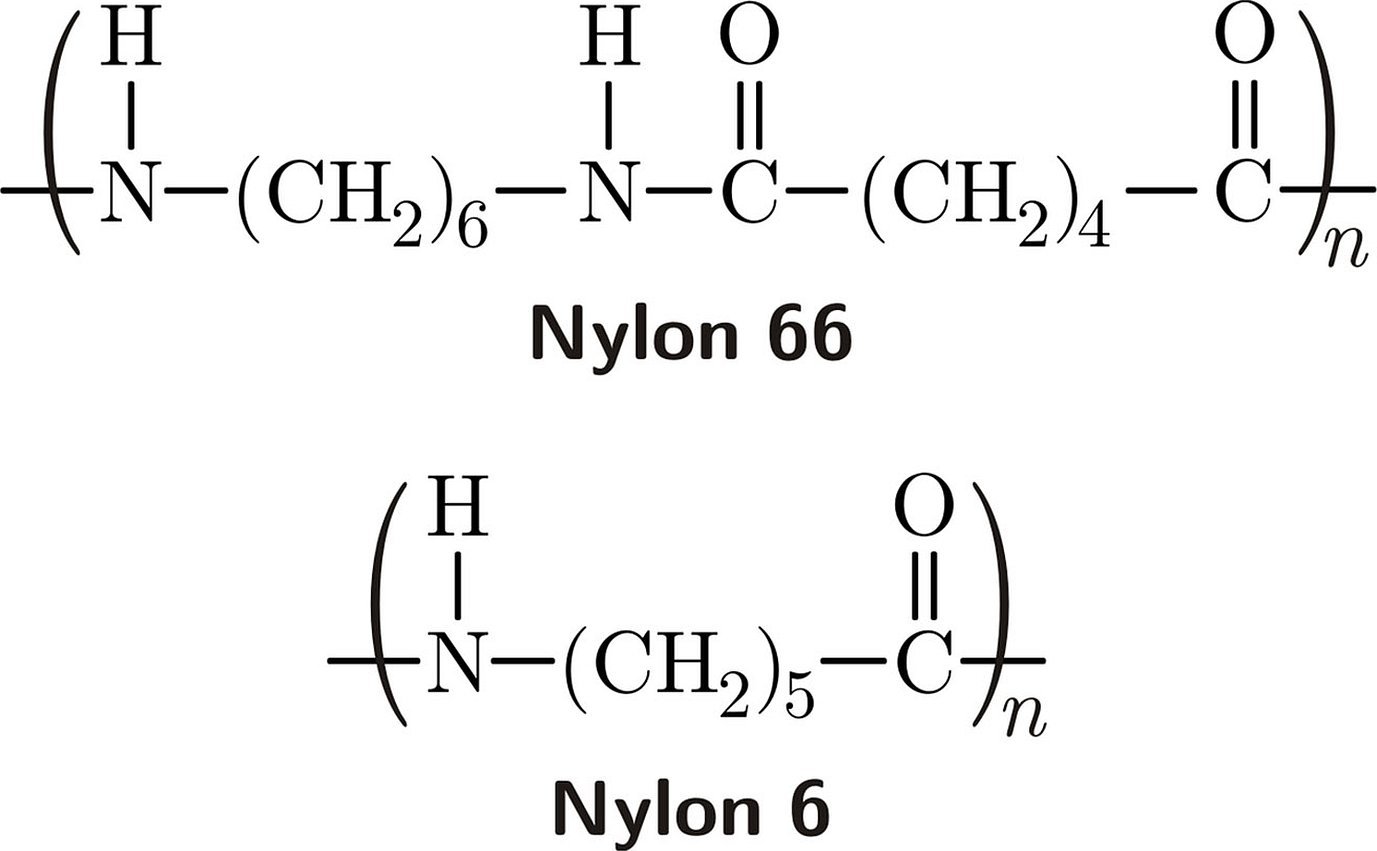

What is polyamide and how is it produced? The process of creating a synthetic substance is carried out in 2 ways:

- Polymerization of caprolactam, which involves conversion into a linear polymer.

- The polycondensation reaction of hexamethylenediamine and acid (adipic), after which polyamides are formed.

Both methods are performed either continuously or periodically. The continuous process is used more often, and there is a noticeable difference between the two modes. Continuous creation of polyamides includes the following steps:

- Preparation. Adipic acid is converted into a salt of hexamethylenediamine. To obtain this component, the acid is combined with methanol in a device that stirs and heats the mixture.

- Polymerization. The resulting solution goes into the polymerization section. There are 3 types of columns: L-shaped, straight and U-shaped. Caprolactam is moved into the column with the solution. The reaction results in boiling.

- The polymer comes out of the column as a molten substance, then it is cooled. Baths are used for this.

- The polymer, divided into strips, is fed to the shredder.

- The resulting crumbs are washed in hot water and cleaned of impurities.

- The crumbs are dried in vacuum-type drying areas.

The continuous polycondensation method is similar to the polymerization method. The difference lies in the principle of processing the source material.

- The process of obtaining salt is similar, however, after obtaining it, it crystallizes and passes on further in the form of crumbs, and not a solution.

- The chain reaction takes place in an autoclave reactor, a cylindrical apparatus with a mixing mechanism.

- Polycondensation occurs with the participation of pure nitrogen. The duration of the process is from 1 to 2 hours. Then the pressure is reduced for an hour, and then the reaction is carried out again. The total amount of time is 8 hours.

- The resulting polyamide is then filtered, cooled and crushed. The material is also dried using hot air streams.

Important! The substance has several forms of release. Poly-e-urea - in the form of crumbs, poly-c-benzamides are released in granules. After additional processing, polyamides are obtained in the form of rods (from 9 mm to 200 mm), sheets of various thicknesses, bushings.

Composition and properties

The composition of polyamide (nylon, and other varieties) includes synthetic fibers, which, in turn, are created through chemical reactions. The original components are obtained from natural coal, oil and gases. The surface is both smooth and rough.

In production, 100% polyamide is used very little. Women's stockings can be made from it, but the material is diluted with others: wool, elastane, etc.

The material has its own special properties:

- It is worth noting the strength of polyamides. Polyamide thread is much stronger than human hair.

- Elasticity. At the same time, the shape remains unchanged.

- Ability to dry quickly.

- Polyamide only melts when exposed to high temperatures, without causing a fire.

- The fabric is lightfast and does not fade.

- Alkali is not harmful to the material.

- The fabric is soft and light.

- Practical in use, the fabric is easy to care for.

- There are many colors, a variety of choices.

In addition, items made from polyamide fabrics have an attractive appearance.

Types of polyamide fabric

Polyamide is a material that can often be found in the production of hosiery. Other fabrics are made from this component. The labels of trousers, T-shirts, jackets usually indicate that polyamide was used in production.

It is also added to viscose. And adding it to natural fabrics can make things elastic, durable and quick-drying. Due to the different degrees of smoothness, polyamide is used in almost all types of clothing.

Please note! Prices for materials can vary significantly. For example, nylon will cost 260 rubles* per 1 kg, and grade "6" polyamide - 620.

Taslan

Taslan is a high-strength fabric, much stronger than nylon. At the same time, the material is "breathable". It has a rep structure and is made using impregnations. Taslan is used for sewing children's clothing, for example:

- Jackets.

- Sportswear.

- Tourist suits.

Winter jackets made of this fabric are especially notable. Thanks to the impregnations, good air exchange is created, and taslan also reliably retains heat. The material is very light - one meter can weigh a little more than 170 g.

The fabrics from which outerwear is sewn also have their own markings. For example, 186T is a light thread, and 310T is a thick one. On the labels of such things, you can see the mark "R/S", which means the presence of additional fibers.

There are also different impregnations of taslan:

- Milky is a white layer applied to the inside, which insulates and allows the item to “breathe”.

- PU — a layer of polyurethane. If you touch this material, the sensations will resemble touching the skin. Waterproof, markings on products indicate the degree of resistance to moisture.

- WR is also a waterproof layer. After its application, water drops that fall are not absorbed, but roll off the surface.

Nylon

This is the very first fabric made from polyamide. In the last century (around the 50s), nylon was one of the most popular fabrics, women's underwear, socks, men's shirts were made from it. The items were inexpensive and did not wear out for a long time.

The material is made with the addition of alcohol and water, it is marked with the number "6". The appearance resembles silk. In addition, the characteristics of nylon are:

- Durability, ability to withstand heavy loads.

- Does not fade or change shape over time.

- The ability to not absorb dust.

- The fabric is quick-drying.

As for air permeability, nylon is inferior here. Things made from it do not let air through well, which can cause allergies.

Nylon is often added to silk and linen, making the products more stretchy and durable. Its presence in the composition can be found on dresses and blouses, as well as on decorative items: curtains, upholstery.

Despite the resistance to dirt, items containing nylon still need to be washed from time to time. But the fabric can withstand washing perfectly. However, it is worth considering that cleaning is carried out at a temperature not exceeding +31 degrees.

Jordan

Jordan appeared in the 21st century and is considered a new generation synthetic fabric. This fabric can be identified by its iridescent color after exposure to light. The fibers are coated with polyurethane, which makes them durable, while the material itself is lightweight and waterproof. Good air exchange - the material "breathes" while being waterproof. Another feature is that Jordan is a fairly warm material. Therefore, it is mainly used to make the following:

- Tents.

- Jackets.

- Overalls.

- Warm tracksuits.

Important! Jordan also withstands frequent washing without losing its properties. The fabric is soft and pleasant to the touch. After cleaning, it dries quickly.

VelSoft

Another type of synthetics that has become famous due to its appearance and qualities. Veloursoft has pile on both sides, which is created from the finest fibers (a hundred times thinner than hair). Due to this structure, the fabric is light, but durable. Veloursoft does not wrinkle, you do not need to iron it every time. It is also resistant to cold air. The material is distinguished by the following criteria:

- Presence of a drawing.

- Color.

- The nature of the thread structure.

Although the fabric retains heat, it does not allow air to pass through well enough. In addition, velsoft tolerates changes in humidity and temperature well, so dressing gowns and children's suits are made from it. You can often see blankets made of this material on the shelves.

Anid

Anid is made from adipic acid, the material resembles nylon. It is produced in the form of monofilaments, staple and filament threads. Anid is in high demand, knitwear and sewing threads are made from it.

Important! The temperature at which items are processed should not exceed 145 degrees.

Elastane

Elastane is used almost everywhere. It is used to make everyday clothes, sportswear, underwear and stockings, festive costumes and performance outfits. The qualities of this material are the same as those of other polyamides - wear resistance, softness, breathability, moisture resistance.

Elastane is quite pleasant to the skin and has the ability to not absorb dirt (stains can be easily washed off by hand).

Tactel

This fabric is made from polyamide 6-6, it has many positive features. The material is "breathable", light, soft and durable. The name is taken from Latin, which means "touch". Outerwear and socks are made from tactel. However, due to such a number of qualities, the price for it is quite high.

Tactel can be:

- Glossy.

- Matte.

- Textured.

- Sparkling.

The types of this material vary, and this determines where the tactile will be used. For example, Tactel-textural is used to sew sports suits. The types differ in the thickness of the threads, appearance (shiny or matte) and elasticity. Tactel is also added to natural fabrics.

How to distinguish polyamide

Polyamide (the characteristics of the material differ significantly from natural ones) is quite easy to identify:

- The fabric feels like silk or cotton. The fabric also has the ability to become electrified.

- If you set fire to a small piece of fabric, it will not burn, but only melt. There will be no extra smells.

- The fabric is not damaged by sunlight or sea water, and most types are breathable.

Usage

In addition to clothing, curtains and upholstery, the following are made with the addition of polyamide:

- Technical footwear and fabrics.

- Ropes.

- Food containers.

- Plastic containers for water, dairy products, cereals and cheese.

- PVC.

You can often come across "polyimide". This is not a mistake, it is a completely different substance, also related to polymers. It is used to produce varnishes, films, adhesives, etc.

Is polyamide harmful?

Although the material is synthetic, it is completely safe and does not harm humans. Fabrics with its addition become durable and do not wear out, the density of polyamides can warm in the cold. Polyamides are used almost everywhere, even children's clothing is made from it. So the material is not harmful at all, but rather practical and cheap.

Care of polyamide clothing

Although polyamide has the ability to retain its shape for a long time and not wear out, simple care of things is required.

- Washing of items (both with and without a print) is carried out at a temperature not exceeding 40 degrees in a delicate mode. If the item is slightly dirty, it is best to wash it by hand.

- It is not recommended to dry the item in a centrifuge. Dry it by hanging it on a rope or on a hanger.

- Usually, items do not require ironing, but if the need arises, the temperature is set to the lowest, otherwise the fabric may “stick” to the iron or be damaged.

Important! Care instructions are also included on the labels, so please pay attention to them.

Advantages and disadvantages

Polyamide fabrics have the following positive qualities:

- Resistant to fire, moisture and sunlight.

- Does not shed.

- Most are breathable.

- Does not require special care.

- Dries quickly.

- Strength and elasticity.

- The fabrics are lightweight, pleasant to the skin, and do not deform.

But there are also some disadvantages:

- High electrification.

- Does not absorb dirt, but absorbs sweat and greasy stains well.

- Exposure to high temperatures during ironing makes the fabric brittle.

- Potential to cause an allergic reaction.

Previously, for many people, the question "What kind of fabric is polyamide?" remained unanswered. But with the receipt of new samples of synthetics and the improvement of existing ones, now almost everyone knows why polyamide is used in clothing and what kind of material it is. Its application is quite wide, and it is in demand in production.